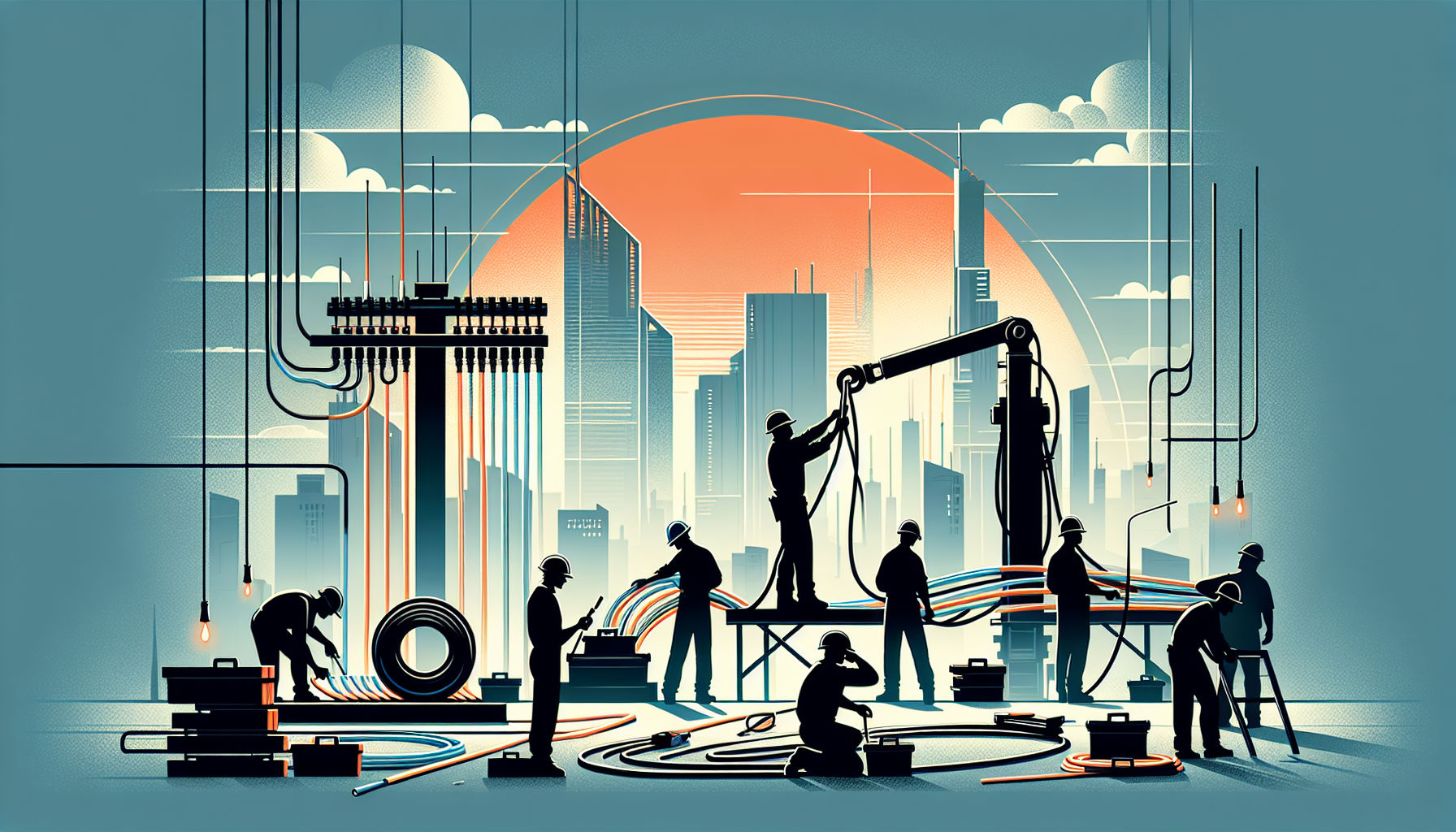

For electrical sub-contractors, mastering conduit bending is crucial. This skill is essential for efficiently navigating the complex pathways of electrical wiring in modern construction projects, ensuring high-quality and speedy installations. The precision and efficiency afforded by advanced bending techniques can significantly impact the quality and speed of installation.

Conduit bending is more than just forming metal; it involves careful planning, measurement, and execution. Techniques and tools applied in this process have evolved, largely impacting work efficiency and accuracy. This evolution has made it essential for subcontractors to stay updated with the latest conduit bending tips and tricks.

Learning advanced conduit bending tips and tricks is invaluable, combining the science behind the techniques with the latest industry practices to enhance efficiency and safety. Here’s what you will learn:

- Techniques: Mastering conduit bending tips and tricks for precise measurements and markings is essential, ensuring every bend meets project specifications without waste.

- Tools: Innovation in the tools used for conduit bending can simplify tasks, improve accuracy, and save time.

- Practical Tips: Real-world advice from experienced professionals can bridge the gap between standard practices and exceptional workmanship.

- Material Management: Effective handling of materials not only prevents waste but also ensures a smooth workflow.

To further enhance your conduit bending skills, consider incorporating step-by-step instructions on common bends, such as 90-degree bends and offset bends.

Utilizing diagrams to visualize the bending process and examples of how to adjust for different sizes of conduit can also be beneficial. Remember, the right tools, like EMT benders, are crucial for achieving precise bends.

Integrating these advanced conduit bending techniques into your workflow, alongside SmartBarrel’s construction management solutions, can significantly elevate the quality of your installations, enabling you to tackle even the most challenging projects with confidence.

Understanding Conduit Bending

Conduit bending is the process of shaping electrical conduit—metal or plastic tubing—to direct electrical wires through buildings and structures. It’s like carefully bending a straw without kinking it, ensuring the wires inside are safely and efficiently routed to their destination. The technique is critical for electrical subcontractors tasked with navigating complex building layouts and ensuring the electrical wiring is properly and safely installed.

Consider the precision required in bending a straw without kinking it; this precision is crucial in conduit bending to avoid damaging the conduit while achieving the desired direction. This technique is essential for electrical subcontractors to navigate around obstacles and ensure that electrical wiring is properly and safely installed.

The significance of conduit bending extends beyond merely directing wires:

- Navigating around obstacles is a common challenge in construction. Conduit bending allows for the seamless integration of electrical systems, regardless of physical barriers.

- Adhering to regulations is not optional. Precision in conduit bending ensures compliance with safety standards and codes, safeguarding both people and property.

Conduit bending, therefore, is not a task to be taken lightly. It requires a delicate balance of strength, precision, and foresight — qualities that every skilled electrical subcontractor strives to embody.

To excel in conduit bending, electrical subcontractors must adopt advanced bending techniques and leverage the right tools.

For instance, using an EMT bender with precise markings can significantly enhance accuracy and efficiency. Additionally, integrating SmartBarrel’s construction management solutions can streamline the tracking of labor and productivity, ensuring projects are completed on time and within budget. Mastering these techniques and tools can lead to work that is not only compliant with regulations but also aesthetically superior and highly functional.

In the following section, we will explore specific conduit bending techniques and tools essential for electrical subcontractors. By integrating innovative technologies, such as SmartBarrel’s suite of construction management solutions, and applying proven methods, subcontractors can significantly enhance the efficiency and quality of their electrical installations.

Prerequisites for Conduit Bending

Importance of Accurate Measurements

Accurate measurements and markings on the conduit before bending are not optional; they’re fundamental. This precision is essential for several reasons:

- Avoiding material waste: Inaccurate measurements can lead to excess cuts and unusable pieces of conduit, increasing project costs.

- Ensuring fit and compliance: Precise bends ensure that the conduit fits perfectly in its intended location, adhering to regulations and design specifications.

Therefore, taking the time to measure twice and bend once is a principle that cannot be overstressed. It ensures that each bend is both necessary and accurately executed, laying the groundwork for a successful installation.

Familiarity with Tools

Understanding and mastering the tools of the trade is equally crucial in conduit bending. Each tool has a specific function and contributes to the overall success of the bending process.

- EMT Bender: The EMT bender is pivotal for making precise bends on Electrical Metallic Tubing (EMT). Its design includes a bending head, handle, and various markings that guide the bending process. Familiarity with an EMT bender’s features allows for consistent and accurate bends.

- No-Dog Level: A no-dog level checks for level and plumb lines during bending, ensuring that the conduit is not only bent at the correct angle but also perfectly aligned.

- Protractor: A protractor aids in measuring the precise angle needed for each bend. This tool ensures that bends meet the exact specifications required for the project.

Each of these tools plays a vital role in achieving successful conduit bends. Familiarizing yourself with their use not only improves efficiency but also contributes to higher quality results.

To further your understanding of how to effectively manage your time and tools during conduit installations, consider exploring resources such as Top 6 Solutions for Construction Time Tracking, which highlights how SmartBarrel’s solutions can streamline your projects, ensuring accurate measurements and efficient use of bending tools.

A practical example of the importance of accurate measurements and tool familiarity can be seen in the Prism Electric case study. Prism Electric leveraged SmartBarrel’s technology to efficiently track time across multiple projects, significantly reducing time card errors and streamlining the payroll process. This case underscores the value of integrating technology to enhance accuracy and efficiency in conduit bending projects.

Please include a placeholder

at an appropriate section to allow for the insertion of dynamic charts that can visually represent the importance of accurate measurements and tool familiarity.

Conduit bending is an art that demands precision, patience, and proficiency with specialized tools. As we’ve explored in this section, preparing adequately by understanding the importance of measurements and familiarizing oneself with essential tools lays a solid foundation for mastering advanced conduit bending techniques. In the following sections, we will share essential conduit bending tips and tricks that can elevate your skills to new heights, ensuring you’re equipped to tackle even the most complex installations with confidence.

How to Master Conduit Bending Techniques

Step 1: Bending 90 Degrees

Mastering the conduit bending tips and tricks for a perfect 90-degree bend, often referred to as a ‘stub up,’ is foundational for electrical installations. Here’s how to master this essential skill:

- Measure the desired stub height, taking into account the required length of the conduit that needs to stand vertically from the bend.

- Subtract the take-up value. The take-up is the amount of conduit that will be used in the bend itself. Different benders have varying take-up values, so refer to your tool’s documentation.

- Align the bender’s arrow with your mark on the conduit. This ensures that the bend will start exactly where you intend it to.

Understanding stub height and take-up is crucial. These factors determine the precise location of the bend on the conduit and ensure that the end product meets installation requirements.

Step 2: Creating a Box Offset

To navigate around obstacles or adjust elevation, a box offset is indispensable. Here’s how to perform this bend with an EMT bender:

- Calculate the bend points based on the obstacle’s height and the distance you need to offset.

- Use the bender’s arrow for initial alignment at your first mark.

- Make two bends at specific angles—this creates a Z-shape which is characteristic of an offset bend.

The significance of this technique lies in its ability to maintain continuity of the conduit run while avoiding obstructions, showcasing why it’s a key skill in complex installations.

Step 3: Executing an Offset Bend

Executing an offset bend effectively is another crucial conduit bending tip and trick, tailored for more precise adjustments in conduit path. Follow these steps:

- Determine the exact points where bends are needed to navigate around obstructions.

- Utilize the bender’s markings for precise alignment and bend angles.

Offset bending plays a critical role in installations where space is limited or obstacles are frequent.

Step 4: Back to Back 90 Degree Bends

For continuous runs requiring sharp changes in direction, back-to-back 90-degree bends are essential. Here’s how:

- Mark your conduit for both 90-degree bends, taking into account the spacing between them.

- Use your bender’s star point for the second bend, ensuring accuracy.

This technique allows for smooth transitions and directional changes in conduit runs without additional fittings.

Step 5: Bending a 3 Point Saddle

Another essential conduit bending tip and trick is mastering the 3-point saddle bend, especially when crossing over an existing obstacle. This involves:

- Marking three points on your conduit: where the saddle begins, peaks, and ends.

- Bending at calculated angles using your bender’s center marking for the peak.

The 3-point saddle effectively elevates the conduit over obstacles while maintaining a seamless run.

Step 6: Straightening a Conduit Bend

Mistakes happen, but with practice and the right techniques, they can be corrected. Learning from experienced peers and practicing with the conduit and bender can significantly improve your efficiency and accuracy. These straightening techniques are vital:

- Gently re-bend the conduit using your knee or a similar method to straighten minor inaccuracies.

- Practice and experience will enhance your ability to make adjustments with minimal effort or waste.

Mastering straightening techniques is a vital part of advanced bending techniques, ensuring that errors do not lead to wasted materials or time.

In conclusion, understanding these advanced conduit bending techniques—and utilizing tools like EMT benders correctly—is paramount. SmartBarrel’s suite of construction management solutions can further enhance your efficiency on-site.

As you continue to refine your conduit bending abilities, remember to explore additional resources and guidance, such as “Keys to Continual Improvement in Construction,” to further enhance your craft. Up next, we’ll discuss the significance of continual learning and staying abreast of industry trends in maintaining high standards in your work.

Essential Tools for Conduit Bending

Understanding the right tools is critical for any electrical subcontractor aiming to enhance their bending skills. For instance, when using an EMT bender to execute a 90-degree bend, start by aligning the conduit’s mark with the bender’s arrow, apply pressure on the foot pedal, and ensure the conduit aligns with the 90-degree mark on the bender.

EMT Conduit Bender Tool

An EMT bender, a crucial tool for electrical subcontractors, is indispensable in achieving precise and efficient bends.

- The design includes features like the rim notch, arrow, star, and degree marks.

- These assist in making accurate 90-degree bends, offsets, and saddle bends.

- The use of an EMT bender can significantly reduce the time spent on manual calculations and adjustments.

Moreover, IDEAL Electrical™ has partnered with BILT® to offer an interactive conduit bending guide, enhancing the learning experience with visual and vocal instructions, as detailed at IDEAL Electrical™.

According to Toolup.com, electricians have access to a variety of conduit benders that optimize bending precision. This advancement in tools, including manual and electric benders, streamlines the process, enabling more complex installations to be completed with greater accuracy.

No-Dog Level

Accuracy is not just about the angle of the bend but also its alignment.

- A no-dog level ensures your bends are perfectly horizontal or vertical.

- It comes with vials marked at 15°, 30°, 45°, plus plumb and level for varied applications.

- This tool is especially helpful for large pipe runs where precision is paramount.

“I find large pipe runs (especially rigid) to be a breeze when using a ‘no-dog’,” says a professional from celtic (no-dog.com). This sentiment echoes the importance of having reliable tools that simplify otherwise complex tasks.

Protractor for Large Pipe Runs

For larger projects, a protractor becomes essential in ensuring that each bend meets the exact specifications required.

- It helps in achieving the precise angle needed for each bend.

- Having a protractor can eliminate guesswork, particularly for large and rigid conduits.

Most professionals rely on common cosecants or have a ‘cheat sheet’ at their disposal. However, as pointed out by steve66 (porcupinepress.com), having a protractor handy can make a significant difference in maintaining consistency across large runs.

Given these essential tools—a 2 x EMT bender, 1 x no-dog level, and 1 x protractor, all available through SmartBarrel—electrical subcontractors can tackle almost any bending challenge with confidence.

The chart above visually represents how these tools can be effectively utilized in various bending scenarios.

Furthermore, understanding how to maintain a safe job site while handling these tools and equipment is crucial. The case study on AG Structures’ Time Tracking Transformation highlights how SmartBarrel’s innovative tools, including those for conduit bending, streamline processes and enhance safety, demonstrating the practical benefits of technology in construction. This resource offers valuable guidelines that complement the safe and effective use of conduit bending tools, ensuring your projects not only meet but exceed expectations.

As we move forward, remember that combining advanced techniques with the right tools and safety measures is key to excelling in conduit installation tasks. Up next, we’ll explore additional strategies that can further refine your conduit bending skills, keeping you ahead in this ever-evolving field.

Practical Tips from Seasoned Contractors

Learning from seasoned professionals, who have navigated countless challenges and developed strategies that streamline the bending process while minimizing errors, is crucial. Their hands-on experience provides invaluable insights for anyone looking to master conduit bending skills and elevate their capabilities.

Cutting Before Bending

Cutting conduit to length before bending is a strategy seasoned contractors often recommend. This approach helps prevent the following common challenges:

- Material waste is significantly reduced when exact lengths are cut first.

- It allows for more accurate planning and execution of bends, aligning with project specifications fully.

Selecting the right tooling based on the bend’s requirements can prevent costly mistakes, as highlighted by The Fabricator. Tooling design should match the bending application, and the simplest solution that meets the application’s needs should be considered first.

Utilizing a Protractor

A protractor is essential for accurate angle measurements. Here are some tips for its effective usage:

- Familiarize yourself with cosecants (multipliers) for common bend angles.

- A protractor ensures that these angles are precisely achieved, eliminating guesswork.

Having a reference for these multipliers aids in achieving exact angles required for a project, which is critical for complex installations where precision is paramount.

Measuring and Marking for Bends

Best practices for marking conduit before bending include:

- Subtracting the “take-up” from the desired stub height.

- Calculating the starting point for a bend based on this subtraction.

This technique ensures that each bend is accurately positioned, leading to installations that are both functional and aesthetically pleasing. The ability to calculate and mark accurately is fundamental in mastering conduit bending techniques.

Adjusting Bends

Fine-tuning bends for perfect alignment involves:

- Gaining familiarity with your conduit bender tool’s markings and their specific purposes.

- Using these markings strategically to adjust bends for ideal placement.

Accurate adjustments can greatly enhance the fit and compliance of conduit runs. This proficiency can differentiate between standard installations and work considered outstanding craftsmanship.

By incorporating these practical conduit bending tips and tricks into your daily tasks, you can streamline your workflow and improve the quality of your projects.

The chart above illustrates the impact of applying these techniques on project efficiency and quality. These bending techniques are essential for any electrical subcontractor aiming for excellence.

The knowledge gained from seasoned contractors, combined with a mastery of bending techniques, empowers you to tackle even the most challenging installations with confidence. Discover how Prism Electric uses SmartBarrel to enhance time tracking and project management, further improving efficiency and quality.

As we transition to the next section, we’ll explore additional resources and innovative solutions, such as how Juneau Construction upgraded its operation with SmartBarrel, enhancing daily logs, headcount accuracy, and safety. This case study exemplifies the practical application of tips from experienced professionals, ensuring you remain at the forefront of industry developments.

Managing Materials and Tools Effectively

The future of conduit bending, and the application of essential conduit bending tips and tricks, hinges on effective material and tool management. Technology’s evolution reshapes the landscape of electrical installations, introducing new challenges and opportunities.

Let’s explore how organizing materials and leveraging custom catalogs can make a significant difference in your workflow.

Organizing Part Numbers and Materials

Innovations such as digital tools or augmented reality for planning and visualizing conduit runs are on the horizon. These advancements promise to simplify the preparatory stages, reducing waste and enhancing efficiency. Here’s how you can stay ahead:

- Digitize your inventory: Transitioning from manual logs to a digital system for tracking part numbers and materials streamlines access and prevents loss.

- Implement barcoding: Using barcodes for materials and tools can drastically reduce the time spent searching for the right components, ensuring a smooth workflow.

The importance of proper applications analysis cannot be overstated. Matching tooling type and design with workpiece requirements is crucial for managing materials effectively.

This approach helps avoid production nightmares, as emphasized by The Fabricator.

Using Custom Catalogs and Lists

Custom catalogs tailored to your specific needs can be a game-changer.

The chart above illustrates the time saved and errors reduced when using custom catalogs and digital inventory systems. Consider the following steps:

- Create personalized lists: Develop a custom catalog that encompasses all frequently used materials and tools, complete with supplier information.

- Leverage technology: Use software solutions that enable you to maintain an updated list accessible from anywhere, facilitating swift decision-making and procurement. SmartBarrel’s technology offers seamless integration with existing systems, enhancing your ability to manage resources effectively.

The emphasis on training and skill development remains paramount. The quality of conduit bending critically impacts the overall safety and functionality of electrical installations.

As we advance into an era where precision and efficiency are at the forefront, staying informed and adept at managing resources becomes indispensable.

By adopting these strategies within your practice, you can ensure that projects are not only completed within timelines but also adhere to the highest standards of safety and functionality.

As we move forward, remember that mastering conduit bending tips and tricks goes beyond the act itself.

For instance, the NV2A Group’s Attendance Management case study demonstrates how SmartBarrel’s technology aids in the organization and maintenance of materials and tools, essential for managing conduit bending operations efficiently.

This comprehensive approach not only elevates your work but also prepares you for the future advancements in this ever-evolving trade.

Conclusion

The mastery of advanced conduit bending techniques marks a significant leap towards achieving unparalleled precision, efficiency, and safety in electrical subcontracting. These techniques stand as testament to the blend of art and science that defines our trade, urging every professional to adopt and adapt to these evolving methods.

By embracing the conduit bending tips and tricks discussed, including advanced bending techniques, you herald a new era of work quality and project execution speed previously unattainable. These conduit bending tips and tricks, rooted in both traditional and innovative bending techniques, are essential for every electrical subcontractor seeking excellence.

The integration of fundamental principles like accurate measurement, marking, and bending underlines the constant pursuit of perfection in our crafts. Such dedication not only elevates the aesthetics and functionality of installations but also ensures compliance with stringent regulations.

Innovations in tools have revolutionized our approach to conduit bending. Yet, it’s the mastery of these technologies, coupled with a firm grasp of traditional techniques, that will set the standard for future projects.

Additionally, the exploration of SmartBarrel solutions, as demonstrated in Kiewit’s Attendance Tracking Efficiency case study, showcases a forward-thinking approach to job site management. Kiewit’s deployment of SmartBarrel devices for real-time, accurate attendance tracking led to significant daily cost savings and improved emergency preparedness, illustrating the tangible benefits of integrating such technologies.

Their suite of construction management tools, including biometric time tracking and cost and productivity tracking, directly complements advanced conduit bending practices by ensuring accurate labor tracking and real-time reporting. This synergy between precise conduit work and efficient project management, facilitated by SmartBarrel, is key to elevating job site productivity and compliance.

For those aiming to streamline their operations and enhance job site productivity, diving into SmartBarrel’s Construction Tracking Software could prove transformative.

In conclusion, as we refine our skills and incorporate advanced techniques into our daily repertoire, let us not overlook the potential of integrating innovative solutions like those offered by SmartBarrel.

This dual focus on honing our craft and leveraging technology paves the way for a future where efficiency, precision, and safety redefine what it means to excel in electrical subcontracting.

This dual focus paves the way for a future of excellence. Honing our craft and leveraging technology like SmartBarrel’s solutions, we aim for efficiency, precision, and safety. This is the new standard in electrical subcontracting.

Frequently Asked Questions

1. What are the rules for bending conduit?

The primary rule for bending conduit is to limit yourself to no more than four quarter bends (a total of 360 degrees) between pull points. This restriction helps prevent damage to the conductor insulation, ensuring that the electrical wiring remains protected and functional throughout its duration.

Following this rule is crucial for maintaining the integrity and safety of electrical installations.

SmartBarrel’s construction management solutions, including real-time reporting and seamless integration, can significantly streamline the conduit bending process. This makes it easier for electricians to apply these conduit bending tips and tricks effectively.

2. What are the 2 dimensions an electrician must know when making a 90-degree stub bend?

When preparing for a 90-degree stub bend, an electrician needs to be familiar with two critical dimensions:

- The distance between the two bends.

- The height of the bend, commonly referred to as stub height.

These dimensions are vital for ensuring that the bend fits accurately within the installation space, meeting both the project specifications and regulatory compliance standards.

3. What is the formula for bending conduit?

The formula significant to conduit bending involves the circumference equation C = 2πR. This equation is pivotal when calculating the developed length for a 90-degree bend.

By applying this formula, electricians can determine the exact length of conduit needed to achieve a precise bend. This minimizes waste and enhances the overall aesthetics of the conduit installation.

4. How can math help with conduit bending?

Math plays an integral role in conduit bending, specifically through the use of sine, cosine, and tangent functions. These mathematical tools are essential for determining the necessary angles for pipe bends effectively.

By leveraging these functions, electricians can execute accurate bends that fit perfectly within their intended space. This facilitates a seamless and aesthetically pleasing installation process.

These conduit bending tips and tricks are designed to improve efficiency and accuracy in your electrical installations.

For a visual guide on conduit bending techniques, see the chart below.