LOCATION

Austin, Texas

CONTRACTOR TYPE

HVAC, Piping, Sheet Metal

TRADE

Mechanical Subcontractor

NO. OF EMPLOYEES

~2.500

INTEGRATIONS

Building Precision at Scale: Meet Dynamic Systems, Inc.

Dynamic Systems, Inc. (DSI) is one of the nation’s top mechanical subcontractors, trusted to deliver HVAC, piping, and sheet metal systems on high-stakes projects across commercial, industrial, and high-tech sectors. With over 2,500 skilled workers and decades of complex builds under their belt, DSI runs lean, builds fast, and delivers with precision at ever.

View the 60-second teaser to hear how DSI uncovered $2.6M in overreported hours and got full field buy-in.

CHALLENGES

Kyle Field at Texas A&M University, College Station, Texas.

DSI Took a Proactive Look at Time Tracking

As a union contractor, DSI is on a weekly payroll cycle, which creates intense pressure for accurate, on-time reporting. Any delay in time capture slows down job costing and payroll processing across hundreds of employees.

“We’re a weekly payroll shop because of all of our union agreements,” said Smith. “And the way we were collecting time, it would take days before that data made it into job costs.”

Before SmartBarrel, DSI was still collecting time on paper. Field workers filled out sheets by hand, turned them into a foreman, and those hours were manually entered into Excel or scanned and sent to payroll. For a union contractor with 2,500 employees and weekly payroll deadlines, this caused massive inefficiencies.

“We were literally walking around the jobsite with pieces of paper,” said Randy Smith, Director of Enterprise Applications at DSI. “Even when we switched to Excel, we still had major inefficiencies. It just wasn’t real-time.”

Labor managers were spending 2–3 hours per week at a single jobsite just collecting time. Payroll data lagged days behind, and job cost accuracy suffered.

SOLUTION

Turning Insight into Action

JW Marriott San Antonio Hill Country Resort and Spa, San Antonio, Texas.

DSI rolled out SmartBarrel on two pilot projects: a large jobsite outside Austin and their fabrication shop. Within days, the system uncovered serious discrepancies.

"The hours that were getting turned into payroll were double or triple what SmartBarrel was actually showing," Smith said. "And in our shop, we caught a bunch of buddy punching."

With facial verification and kiosk check-in, SmartBarrel immediately gave DSI real-time visibility into who was on-site and what time each worker had checked in and checked out. Foremen no longer had to chase hours, and supers could see attendance and productivity across jobs.

"One of our supers went to a quick training session and ran back to his job, set up his site and his crew in SmartBarrel, and he was done. I didn’t even have to help him,” added Smith.

Still relying on spreadsheets to know who’s on site?

RESULTS

Big Wins From a Bold Rollout

GlobalFoundries Fishkill Fab 10 Upgrade, Hopewell Junction, New York.

DSI’s project managers, supers, and foremen quickly recognized the value of SmartBarrel’s real-time data and accurate labor hours. They began requesting additional reporting views, such as those who worked less than 40 hours or who hadn’t shown up in multiple days, to manage crew performance and attendance trends better. SmartBarrel’s data has also become part of DSI’s broader business intelligence ecosystem.

"We use SmartBarrel data in our Power BI dashboards—it's part of our operations map," explained Smith.

SmartBarrel is now a standard operating procedure at DSI. It’s deployed on more than 50 projects. The results speak for themselves:

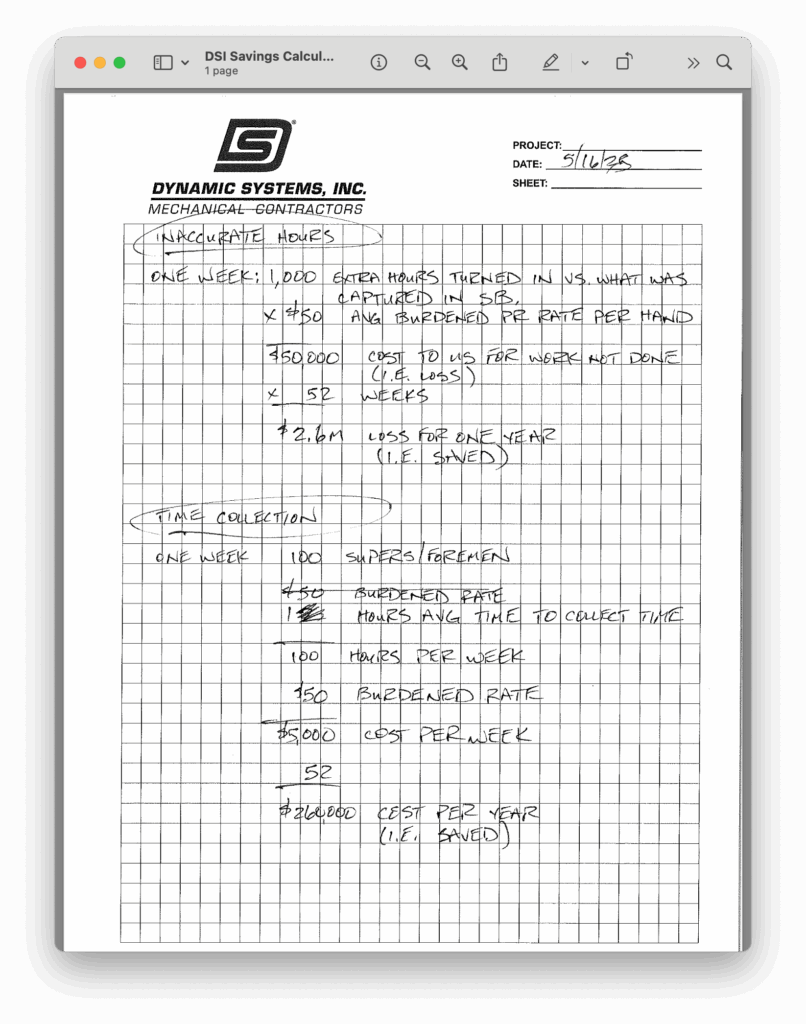

- $260,000/year saved just from reducing the time supers and foremen spend collecting hours

- $2.6 million/year in potential savings from overreported and inaccurate time

- 100% increase in field visibility

- Full field buy-in: Foremen and supers are sending in feature requests

"SmartBarrel gave us accurate labor hours in real time," Smith said. "That visibility has been a huge win."

Caught $2.6M in wasted labor costs? You bet they did.

The SmartBarrel Advantage for Top Mechanical Subcontractors

For a nationwide union contractor like DSI, trust in reported hours isn’t just a nice-to-have—it’s essential for managing payroll, job costs, and crew accountability. SmartBarrel delivered the biometric verification, automated workflows, and real-time data they needed to operate at scale, without slowing down.

With SmartBarrel, DSI finally had field-verified time data they could trust, feeding directly into their Power BI dashboards and soon, Viewpoint Vista. Foremen and supers who weren’t sure about change are now embracing SmartBarrel and coming up with new feature ideas.

Tired of buddy punching and unverified hours?

Next Up

Deeper ERP integration. DSI is actively connecting SmartBarrel to Viewpoint Vista to streamline setup, reduce duplication, and sync labor records across systems.

“We’re setting it up so I can pull in all our active employees from Vista, and it’ll bring over their info—employee number, trade, union details, and more,” said Smith.

SEE IT IN ACTION

Want to hear it from Randy himself? Watch the full on-demand webinar and see how DSI caught $2.6M in hidden labor costs.