Construction cost tracking fails for a simple reason that rarely shows up in software demos or budget reviews: data quality.

Job costing platforms, detailed spreadsheets, and real time tracking dashboards can be powerful tools, but only when the data feeding them is reliable. In practice, many construction companies are making high-stakes decisions on information that’s incomplete, delayed, or wrong.

If your time data is wrong, your labor costs are wrong. And when labor represents 40–50% of total project costs, inaccurate labor data undermines every cost report, forecast, and dashboard that depends on it.

This guide explains what construction cost tracking actually involves, the methods that work in practice, and the specific data requirements each one depends on. More importantly, it shows why accurate time data is the foundation that allows cost tracking systems to produce reliable, actionable insight.

We’ll examine the operational gaps that quietly erode margins, compare the software approaches that address them, and outline best practices that protect profitability. Because accurate cost tracking starts with a basic requirement: knowing, with confidence, how many labor hours were actually worked.

The Basics of Construction Cost Tracking

What is Construction Cost Tracking?

Construction cost tracking is the systematic process of monitoring and recording all expenses throughout a project lifecycle – from preconstruction through closeout. It’s how you know where money’s going, where it’s been, and where it’s about to go.

But here’s where most definitions miss the mark: Construction cost tracking goes beyond simply recording expenses. It requires accurate data at the point of work to effectively track every dollar spent, clear alignment with budgets and cost codes, and timely analysis that allows teams to address issues before they impact margins.

Cost Tracking Hierarchy

Level | What It Does | Focus |

Data Capture | Where costs originate | Field labor time tracking |

Cost Classification | Organizing expenses | Categorizing into meaningful groups |

Cost Analysis | Comparing & identifying | Actual vs. budget, trends, variances |

Cost Control | Taking action | Decisions based on data insights |

Most contractors focus on steps 3 and 4 while missing how much step 1 determines their success. According to the Construction Financial Management Association, contractors who implement real-time construction project cost tracking improve project efficiency by an average of 15-20%. But that’s only true if the underlying data is accurate.

The Cost Tracking Paradox: You need real-time data to make timely decisions, but most construction companies are working with yesterday’s guesses penciled onto a timesheet that won’t reach the office for another three days.

Why Labor Cost Accuracy Is the Foundation

Labor typically represents 40-50% of total construction project cost. For specialty contractors doing self-perform work, that number can hit 60-70%. Yet labor is hard to track accurately because it requires:

- Knowing who’s actually on-site (not who said they’d be there)

- Verifying start and stop times (not rounded guesses)

- Assigning hours to correct cost codes (in real-time, not days later)

- Tracking productivity across multiple projects and sites simultaneously

- Managing complex classifications (union vs. non-union, prevailing wage, overtime calculations)

Here’s the brutal math: If just 10% of your labor hours are inaccurately reported – through buddy punching, time rounding, or hours being entered at the end of the week – that’s a 4-7% hit to your total project costs and financial health. On a $5M project, that’s $200K-$350K. On a $50M project, you’re looking at $2M-$3.5M in uncontrolled costs.

No wonder margins erode and cost performance becomes harder to predict.

Construction Cost Tracking Methods & Techniques

Construction cost tracking relies on several core methods. In this section, we focus not just on how each method works, but on the specific data accuracy requirement that determines whether it produces reliable insight or misleading reports.

Job Costing

Job costing tracks all expenses (labor, materials, equipment, subcontractors) for a specific project, comparing actual costs against budgeted costs for better budget management.

Why it matters: Job costing provides visibility into financial performance while a project is still underway, when corrective action is possible. Without it, profitability is often assessed only after closeout, when cost overruns can no longer be addressed.

Critical success factor – Accurate labor hours: Job costing is only as reliable as the labor data feeding it. When hours are rounded, entered after the fact, or assigned to cost codes based on memory rather than measurement, job cost reports lose accuracy and decision-making suffers. Effective job costing requires:

- Precise clock-in and clock-out times, not rounded intervals

- Verified worker identity, ensuring hours are attributed to the correct individual

- Cost codes assigned at the time work is performed, not retroactively

- Cross-project visibility when managing multiple active jobs simultaneously

Cost Code System

Cost codes are the categories you use to classify construction work – typically following CSI MasterFormat divisions (like 03-Concrete, 26-Electrical, etc.) or your company’s custom breakdown.

Why it matters: Cost codes let you track productivity and costs related to specific tasks at a granular level. Instead of just “electrical work,” you can see costs for “rough-in,” “fixtures,” “low voltage” separately. That level of detail makes it possible to identify which activities are performing as expected and which are driving cost variance, supporting tighter budget control.

Critical success factor: Eliminating manual cost code entry

Cost code accuracy breaks down when classification relies on memory or manual assignment after the work has already occurred. Delayed or retrospective coding increases error rates and reduces confidence in the resulting cost reports, especially on complex projects with multiple crews and concurrent activities.

Better approach:

- Accurate cost code tracking depends on minimizing manual steps:

- Workers check in and out using biometric verification

- Time data flows automatically into verified timesheets

- Project managers and foremen assign cost codes quickly using pre-populated, validated time records

- Cost coding happens close to the time of work, not days later

This approach reduces guesswork, lowers administrative burden, and improves the reliability of cost data across projects.

Activity-Based Costing

Activity-based costing (ABC) allocates costs based on actual activities performed rather than broad categories. Instead of just tracking “labor,” you track “formwork installation,” “concrete placement,” “finishing,” etc.

Why it matters: ABC gives you surgical precision on where time and money go. You can identify that formwork takes 30% longer than estimated while concrete placement is under budget. This level of expense tracking improves accuracy in decision making for future construction projects.

Critical success factor – Detailed time capture: ABC requires knowing not just how many hours but which specific activities consumed those hours. This requires systems that capture accurate, activity-level time data as work is performed, rather than relying on memory at the end of the week.

Unit Cost Tracking

Unit cost tracking calculates cost per measurable unit of work – cost per square foot of drywall, per cubic yard of concrete, per linear foot of conduit, etc.

Why it matters: Unit costs let you benchmark productivity across projects and improve estimating accuracy for future bids. If you know your fully burdened cost per linear foot of EMT conduit, including labor and material, you can bid more competitively and with greater confidence.

Critical success factor – Clean historical data: Unit cost tracking only works if you have accurate historical data. That means years of accurate time tracking feeding accurate job costing. When historical data lacks accuracy and consistency, unit cost benchmarks inherit those flaws.

Time & Material Tracking

Time and Material (T&M) tracking records billable labor hours and material usage for projects billed based on actual costs plus an agreed markup, rather than a fixed price. Accurate, well-documented tracking is essential to maintain transparency and trust with clients.

Why it matters: T&M contracts rely on the contractor’s ability to substantiate every billed cost. When labor hours or material usage can’t be clearly verified, invoices are more likely to be questioned, delayed, or reduced. Weak documentation doesn’t just create disputes, it undermines cash flow and confidence in project financials.

Critical success factor – Audit-ready documentation: Effective T&M tracking depends on documentation that is complete, consistent, and defensible during reviews or disputes. That means time records with verified worker identity, clear timestamps, and location context that demonstrate when and where work occurred. Systems that capture this information automatically reduce disputes, discourage time abuse, and provide the level of traceability T&M billing requires

Earned Value Management

Earned Value Management (EVM) compares planned value (what you planned to spend), actual cost (what you actually spent), and earned value (value of work completed) to predict final project outcomes.

Why it matters: EVM gives you predictive power for successful project delivery. Instead of just knowing you’re over budget, you can forecast the final cost variance and take corrective action now.

Critical success factor – High-quality, timely data from all sources:

Earned Value Management (EVM) is mathematically rigorous. When it’s fed incomplete or inaccurate inputs, it produces forecasts that appear precise but are fundamentally misleading. Effective EVM depends on reliable labor time data, accurate material tracking, and updates frequent enough to reflect current project conditions.

Many contractors struggle to apply EVM successfully not because of the methodology itself, but because their underlying data lacks the consistency and timeliness EVM requires. In practice, EVM exposes data quality problems rather than compensating for them.

Benefits of Real-Time Construction Cost Monitoring

Real-time construction cost monitoring delivers tangible operational benefits beyond generic promises of better visibility. Its value shows up in how quickly teams can detect and respond to cost and productivity issues.

Early warning system

Real-time monitoring surfaces cost and productivity issues while corrective action is still possible. Labor cost spikes become visible early in the workweek rather than after reports are finalized, and productivity declines on specific cost codes can be addressed before they materially impact the overall budget.

The alternative is delayed reporting, where field activity is captured days or weeks after the work occurs. By the time issues appear in financial reports, their impact has already compounded. At that point, teams are reacting to past conditions rather than actively managing current project performance. Delayed data doesn’t just slow decisions, it removes the opportunity to make the right ones.

T&M Billing Confidence Through Accurate Reporting

Accurate, verifiable time records strengthen confidence in Time and Material billing. When billable hours are supported by verified identity, timestamps, and location context, invoices are easier to review and less likely to be questioned.

Strong documentation reduces friction during progress billing by clearly substantiating labor charges. Instead of spending time reconciling hours after the fact, teams can focus on maintaining transparency and keeping billing cycles moving without delays.

In T&M work, confidence in the data directly impacts how quickly and smoothly invoices are approved.

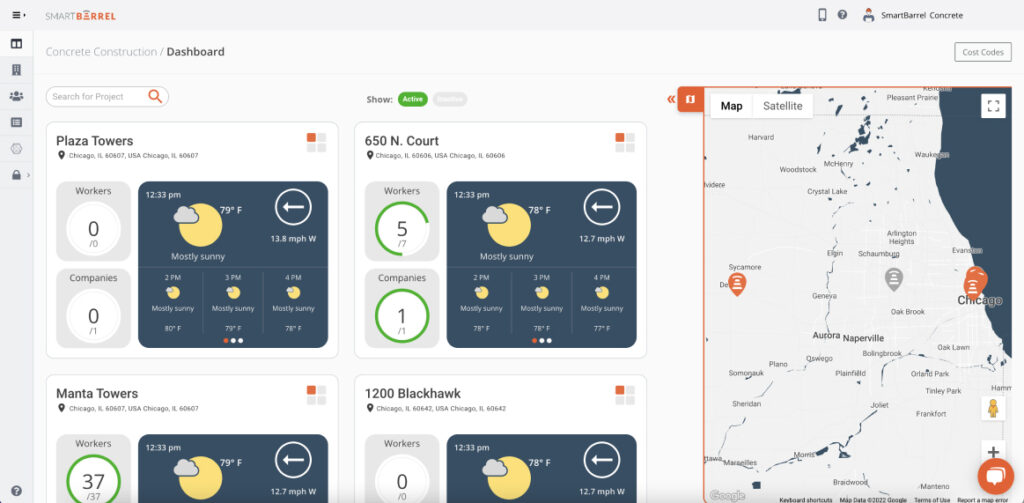

Multi-Site Visibility Across Multiple Projects

Managing multiple active jobsites requires consolidated, cross-project visibility. Leadership teams need to understand labor costs across the entire portfolio without relying on fragmented or delayed reporting from individual projects.

Real-time cost monitoring provides a centralized view of labor spend across all active jobs, allowing executives to assess performance, monitor budgets, and identify emerging issues across the operation. Instead of reviewing outdated summaries, teams work with current, consistent data that reflects actual field activity and supports better-informed decisions. As project counts grow, centralized and timely labor visibility becomes essential for maintaining financial control.

Predictive Insights (When You Have Clean Data)

Here’s where it gets powerful: Clean, structured data enables forecasting. You can see patterns – this crew always takes 10% longer on rough-in than estimated. This type of project always runs into material delays in week 3. Winter weather slows your concrete crews by 15%.

Those insights let you bid better, staff better, and schedule better. But only if the underlying data is accurate. Clean data doesn’t guarantee perfect forecasts, but without it, forecasting isn’t credible.

Common Challenges in Construction Cost Management

Construction cost tracking typically breaks down for a small number of repeatable, operational reasons. These are not theoretical issues or edge cases. They show up consistently across projects and organizations.

1. Time Theft and Buddy Punching

The problem: Workers clocking in for absent colleagues. Rounding 7:36 to 7:00. Leaving an hour early but writing down full time. This isn’t a people problem. It’s a system design problem. When time capture relies on trust alone, small inaccuracies accumulate into material cost variance.

The impact: Industry research shows time theft creates unexpected expenses $4,285 per worker annually. In labor-intensive operations, that exposure compounds quickly across crews, inflating labor costs and distorting job cost data long before the issue becomes visible in financial reports. These losses add up quietly and erode margin predictability.

Why it happens: Paper timesheets. Fob systems where one worker carries 15 keychains and clocks everyone in. Mobile apps that let workers clock in from the parking lot. Any system that doesn’t verify WHO is clocking in and WHERE they’re clocking in from undermines confidence in reported labor hours.

2. Manual Data Entry Errors

The problem: Foremen filling out timesheets from memory on Friday afternoon. Office staff transcribing handwritten timesheets into accounting software. Multi-step processes where data gets corrupted or lost between the field and the office.

The impact: Even if there’s no intentional fraud, these issues become an ongoing process. Studies show manual data entry has error rates of 1-4%. That doesn’t sound like much until you realize it means 1-4% of your labor cost data is wrong. On a $10M annual payroll, that’s $100K-$400K in potentially inaccurate cost data affecting your decisions and compromising accurate reporting.

Why it happens: Asking field teams to do manual entry. Disconnected systems that don’t talk to each other. Batch processing instead of real-time flow. Project managers spending hours reconciling conflicting data.

3. Temp Labor and Subcontractor Accountability

The problem: Managing labor costs becomes more complex when work is performed by multiple external parties. In addition to direct employees, many projects rely on temporary labor from staffing agencies and hourly subcontractors for specialized work. While these arrangements are common and often necessary, they introduce an additional layer of risk when billed hours cannot be independently verified.

The operational reality: In multi-company workforce environments that combine W-2 employees, temp labor, and subcontracted crews, cost tracking depends on verification methods that work consistently across organizations. Without that consistency, labor reporting becomes fragmented and unbudgeted costs can accumulate without clear visibility into their source.

Why it happens: Reliance on verbal confirmations, summarized invoices, or timesheets submitted by third parties limits transparency. When there is no independent system to confirm who was on-site and when work occurred, validating billed hours becomes difficult and disputes become more likely.

4. Multi-State Complexity

The problem: Managing projects across multiple states introduces significant complexity. Jurisdictions like Texas, Florida, and California each have different prevailing wage requirements, union agreements, and overtime rules. Cost tracking systems must account for these variations automatically. When they do not, compliance risk increases and labor costs become harder to model accurately.

The impact: Errors in prevailing wage calculations can lead to back pay obligations and financial penalties. At the same time, applying incorrect labor burdens distorts job cost data and weakens confidence in profitability analysis. Together, these issues introduce financial risk that is often discovered only after the fact.

Why it happens: Many systems are designed for single-state operations. Manual rule tracking, spreadsheet-based adjustments, and limited automation make it difficult to apply jurisdiction-specific labor rules consistently across projects

5. Integration Failures (Data Trapped in Silos)

The problem: Time data lives in one system. Job costing lives in another. Payroll is separate. ERP is separate. Project management is separate. You’re manually exporting and importing data between systems, creating lag, errors, and gaps.

The impact: You can’t make fast informed decisions when data is scattered across six systems. By the time you manually compile everything into a coherent picture, the moment to act has passed. You’re losing control of project finances without realizing it.

Why it happens: Buying best-of-breed tools without considering integration. Legacy systems that don’t play nice with modern APIs. Lack of middleware connecting your tech stack. Project managers spending time reconciling data.

5 Best Construction Cost Tracking Software Solutions

Effective construction cost tracking typically relies on several tools working in coordination rather than a single application. Accurate data must move reliably from the point of work in the field, through consistent classification in job costing systems, and into analysis and reporting tools that support decision-making.

This section outlines the core components of that system, starting with the foundation.

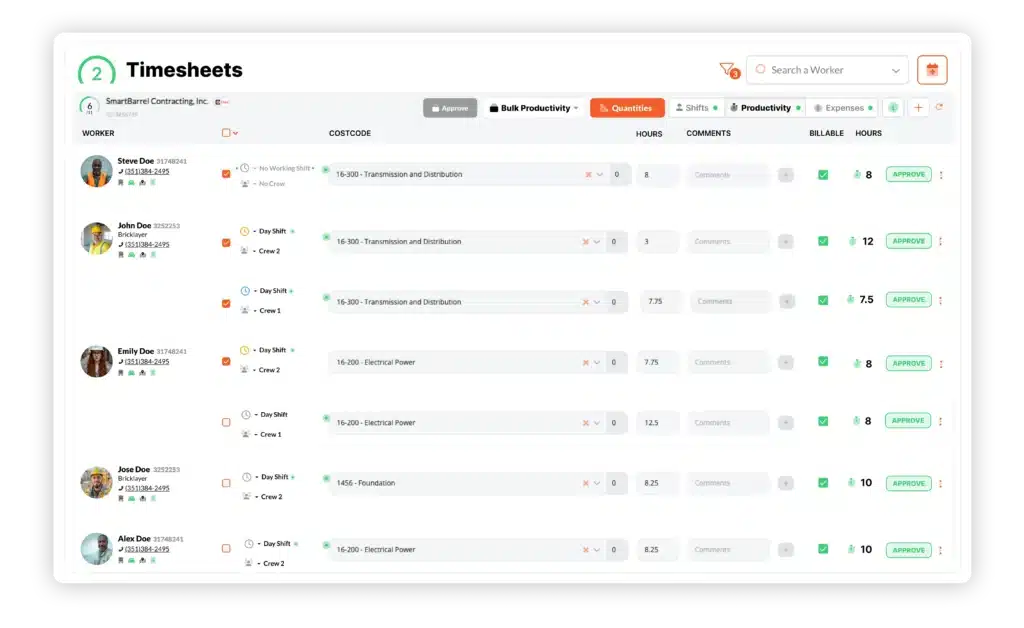

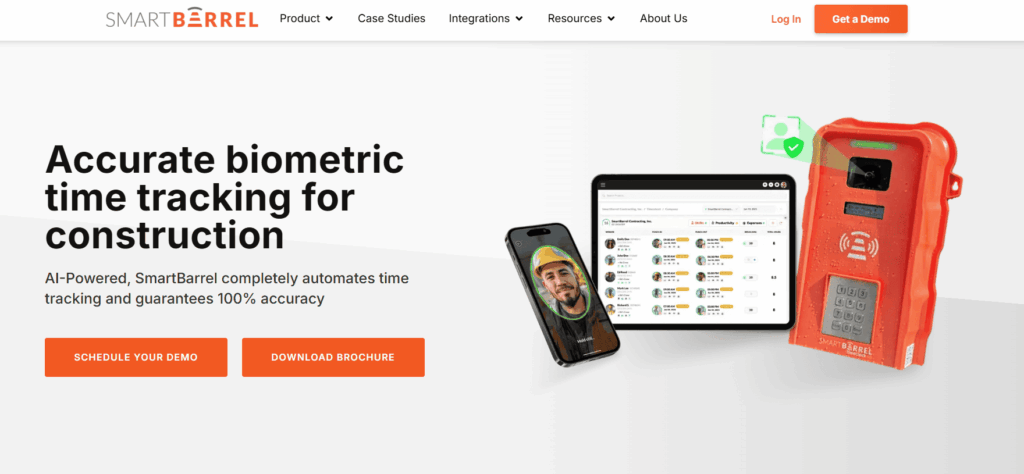

SmartBarrel – The Data Accuracy Foundation

Most cost tracking and project management systems assume labor time data is accurate. SmartBarrel is designed to improve the reliability of that data at the point of capture.

What it is: SmartBarrel is a biometric, facial-verification time tracking system built specifically for construction environments. It supports fixed hardware devices for large jobsites and mobile applications for smaller or distributed crews. By minimizing manual entry and capturing time data as work occurs, it improves accuracy at the source.

Why it’s different: SmartBarrel is not a cost tracking or project management tool. It focuses specifically on labor time capture, providing verified time data that feeds into ERP systems, job costing platforms, payroll, and reporting tools. By strengthening the quality of labor data upstream, it supports more reliable cost tracking, forecasting, and financial analysis downstream.

Key features:

- Biometric facial verification (not facial recognition – critical distinction): Workers clock in using their phone number, and the device captures a photo at the time of punch-in. That image is automatically compared against previous photos associated with the same worker to confirm it is the same person clocking in. This approach ties each time entry to a visual identity record. No photoshoot required – system self-learns workers. System automatically flags any suspected buddy punching.

- Built-in LTE connectivity: Works anywhere – parking structures, basements, remote sites. No WiFi dependency. No “I couldn’t clock in because there was no signal” excuses. Enables accurate reporting from any location.

- No phone required: Workers punch in using their phone number or a fob. Excuse-free solution that works for everyone, including workers with no smartphone.

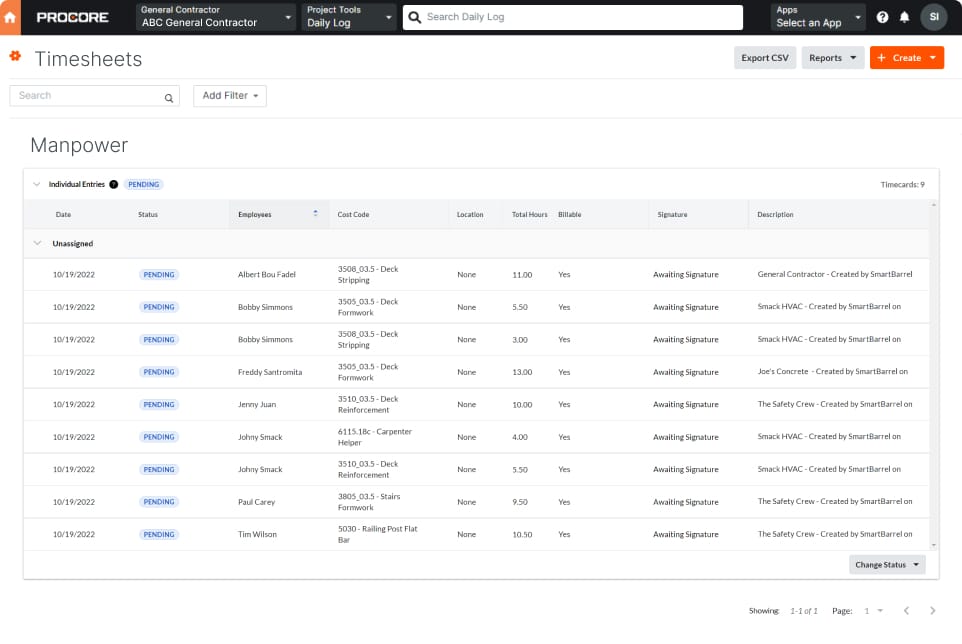

- Automatic data capture: Each clock-in captures verified time, location, and worker identity data automatically at the point of work. That verified time data then flows into downstream workflows, where cost codes and other classifications can be applied using accurate, validated records.

- Pre-populated timesheets: Verified time data flows directly into timesheets, enabling foremen to review punches and assign cost codes using validated records rather than retrospective estimates.

- Real-time integration: SmartBarrel integrates with platforms including Procore, Vista, and CMiC to support downstream payroll, job costing, and reporting workflows.

Best for: Specialty contractors with 100-5,000 workers, running multiple projects simultaneously, who need bulletproof time data feeding their cost tracking systems. Particularly strong for electrical, MEP, concrete, drywall, solar contractors doing T&M work or managing a mix of direct employees and temp labor across multiple construction projects.

Pricing model: SmartBarrel is priced per device and per active user. Customers report recovering the cost of the system within the first weeks of deployment through direct payroll savings from improved labor verification.

LiveCosts

What it is: Real-time cost tracking platform that pulls data from multiple sources (payroll, procurement, equipment) and presents unified cost picture across construction projects.

Strength: Live updating of actual costs vs. project budget. Strong visualizations showing cost trends and variances. Good cost tracking features for monitoring budgets in real-time.

Integration dependency: Requires accurate input data from time tracking, procurement, and accounting software. Works best when paired with verified time data from systems like SmartBarrel.

Best for: Contractors who already have their data sources (time tracking, procurement) locked down and need better visualization and analysis tools for maintaining budget control.

Buildern

What it is: All-in-one construction management software including estimating, project management, and cost tracking.

Strength: Covers multiple functions in one platform. Good for smaller construction companies who want consolidated tools for delivering successful projects.

Integration dependency: Has its own time tracking module, but effectiveness depends on field teams actually using it consistently and accurately. Automated alerts help but don’t solve underlying data quality issues.

Best for: Growing contractors (under 200 employees) consolidating from spreadsheets to an integrated platform for improved project efficiency.

Mastt

What it is: Cost management and reporting platform focused on large capital projects throughout the project lifecycle.

Strength: Built for complex, multi-stakeholder projects with sophisticated reporting requirements. Strong budget vs. actual tracking with drill-down capability for specific project analysis.

Integration dependency: Pulls data from multiple sources including time tracking, procurement, and subcontractor systems. Integrated cost reporting is only as reliable as the data feeding it. Inaccurate or delayed inputs from time tracking, procurement, or subcontractor systems directly undermine visibility into actual project spending.

Best for: GCs and large contractors on major projects requiring detailed cost reporting for owners and stakeholders. Strong purchase orders integration and progress billing capabilities.

RedTeam

What it is: Field-first project management software with integrated job costing and financial management.

Strength: Mobile-first design. Good adoption with field teams. Connects field activities to financial outcomes for improved decision making.

Integration dependency: Has built-in time tracking, but limited biometric verification. Works better when integrated with dedicated time tracking for improved accuracy at the data source.

Best for: Commercial contractors focused on getting field teams using mobile tools for daily reporting and cost tracking across multiple construction projects.

5 Best Practices for Construction Cost Tracking

Effective cost tracking relies on disciplined processes, not generic advice. The practices below focus on actions that consistently support reliable budgets and stronger project control.

1. Establish a Detailed Budget Before Work Begins

Detailed budgeting is foundational, but its reliability depends on the quality of the data behind it. A project budget is only as strong as the historical information used to build it.

The practice: Develop budgets using detailed cost codes that reflect how work is actually performed. Include labor, materials, equipment, and hourly subcontracted work. Apply contingencies based on project type, complexity, and observed risk patterns from similar past projects.

The data dependency: Historical budgets built on incomplete or unreliable labor data carry forward hidden assumptions. Before relying on past job costs, ensure the underlying time data is accurate and consistently captured. Improving time tracking upstream strengthens every downstream budgeting decision.

Specific tactic: Before budgeting a major new project, review job cost reports from several comparable completed projects. Assess whether labor hours were captured consistently and can be reasonably verified. Where confidence is low, treat those figures as directional rather than definitive until more reliable time data is available.

2. Promote Clear Communication Between All Stakeholders

The practice: Make cost data accessible to the people who rely on it, including project managers, superintendents, foremen, estimators, and leadership. Clear access to relevant cost information supports transparency and enables better decisions across the organization.

The pitfall: Accessibility does not mean giving every user full access to the ERP system. It means delivering the right data to the right role in a format that supports how decisions are actually made.

Specific tactic: Use role-based dashboards to tailor visibility:

- Foremen see their crew’s verified time and assigned cost codes

- Project managers see labor costs compared to budget across all cost codes for their projects

- Leadership sees labor performance across projects, with alerts for material budget variance

- Estimators see historical unit costs and productivity metrics

Make cost data easy to access, but intentionally scoped. The goal is clarity and action, not information overload.

3. Establish Cost Categories for Better Control

The practice: Use a consistent cost code structure integrated with your accounting system so labor and cost data can be compared meaningfully over time. Cost codes should be defined and maintained in the systems of record, such as your ERP or construction management platform, and applied consistently across jobs.

The burden problem: Cost code accuracy breaks down when field teams are forced to search through long, irrelevant lists. Field-facing workflows should present only the cost codes that apply to the project and the work being performed, without requiring excessive navigation or manual lookup.

Specific tactic: Reduce friction by leveraging systems that surface relevant and recently used cost codes. When foremen assign cost codes using verified time data and familiar selections, classification becomes faster and more consistent.

4. Use Construction Time Tracking Software (This Is the Foundation)

This is where the cost tracking system comes together. Accurate time tracking underpins nearly every other cost control practice in construction.

Why this matters more than everything else: Labor is the largest variable cost on most construction projects, and it is also the most difficult to measure consistently. When labor time is captured accurately and reliably, downstream processes such as job costing, budget monitoring, forecasting, and estimating all improve. When time data is inconsistent or delayed, those same processes inherit uncertainty and error.

Getting labor time right does not solve every cost problem, but it significantly improves the reliability of the systems built on top of it. Without accurate time data, even well-designed cost tracking tools struggle to produce dependable insight.

What “right” looks like:

Automatic capture, not manual entry: Workers check in using biometric verification, and time data is captured automatically at the point of work. This reduces reliance on handwritten timesheets, memory-based reporting, and manual entry, improving accuracy and consistency in labor cost data.

Real time tracking, not batch processing: Time data is available shortly after it is captured rather than days later through delayed timesheet submission. This allows teams to monitor labor costs and budget performance while work is still in progress across multiple jobsites.

Verified, not assumed: Clock-ins are tied to verified worker identity, location context, and timestamps. Labor records are supported by objective data, improving confidence in reporting and transparency with stakeholders.

Integrated, not siloed: Verified time data flows into payroll, job costing, and ERP systems through structured integrations. A single time entry captured in the field supports multiple downstream workflows, helping ensure that project management, accounting, and field operations work from a consistent source of labor data.

The ROI calculation: Consider a contractor with approximately 200 field workers across multiple active projects. Industry research has estimated that time theft and time leakage can cost contractors an average of $4,285 per worker annually, representing roughly $857,000 per year in potential labor exposure at this scale.

If improved time verification and reporting reduced even a portion of that leakage, the financial impact would be material. Recovering a fraction of inaccurate or unverified labor hours can translate into hundreds of thousands of dollars per year in reduced payroll.

Additional benefits often include lower administrative effort associated with manual timesheet handling, faster payroll processing, and fewer billing disputes on Time and Material work. Taken together, these effects commonly outweigh the annual cost of time tracking systems for mid-sized operations, producing a strong return within the first year of use.

While actual results vary by organization, contractors with large field workforces frequently see labor verification improvements pay for themselves quickly through direct payroll impact.

5. Be Open to Budget Adjustments (But Know WHEN to Adjust)

The practice: Project budgets are planning targets, not fixed constraints. When conditions change, such as scope adjustments, material price increases, or schedule disruptions, budgets should be revisited to reflect reality. At the same time, it is important to distinguish between legitimate changes and cost growth driven by execution issues.

The data requirement: Budget adjustments require timely, reliable cost data. Teams need visibility into whether variances are driven by approved scope changes or by productivity and execution problems. That distinction determines whether the right response is a budget revision or a process correction.

Specific tactic: Use variance-based review thresholds rather than waiting for full budget exhaustion. For example, teams may trigger a review when a cost code reaches a defined percentage of its planned budget. When that threshold is reached, the focus should be on understanding the cause. Is the variance explained by scope or conditions, or does it indicate inefficiency that needs to be addressed?

Without timely cost data, these reviews happen too late. By the time overruns are visible in reports, opportunities to intervene have often already passed, limiting the options available to project teams.

Construction Cost Tracking FAQs

How to effectively track construction project costs across the entire project?

Effective construction cost tracking starts with reliable labor data, since labor typically represents a significant portion of total project costs. Improving the accuracy of time capture reduces downstream errors in job costing, budgeting, and forecasting.

From there, costs should be organized using consistent cost codes and supported by systems that allow time and cost data to flow into payroll, job costing, and financial reporting without unnecessary manual handling. This improves consistency and reduces delays between field activity and financial visibility.

Finally, project teams should review cost performance frequently enough to identify issues while corrective action is still possible. Many organizations use variance-based alerts or review thresholds to flag emerging issues before budgets are exhausted. The common thread across all approaches is capturing accurate data at the source and making it available quickly to the people responsible for managing cost and performance.

Why is construction cost control important?

Most specialty contractors operate on thin net margins, often in the low single digits. In that environment, even modest cost overruns can materially reduce or eliminate project profitability. Effective cost control provides the visibility needed to understand where money is being spent and whether projects are performing as expected.

Accurate cost data supports more competitive and confident bidding, improves cash flow management, and reduces exposure during change order and billing disputes. It also enables contractors to scale operations without losing financial discipline. Without reliable cost control, decisions are made with incomplete information, increasing the risk of margin erosion and financial surprises late in the project lifecycle.

What are the key performance indicators for construction cost tracking?

Effective construction cost tracking relies on a small set of financial and operational indicators reviewed consistently throughout the project. Commonly used KPIs include:

- Cost Performance Index (CPI): compares actual costs to budgeted costs

- Labor productivity: measures output completed per labor hour

- Budget consumption rate: compares the percentage of budget spent to the percentage of work completed

- Variance at completion: estimates final project cost relative to the original budget

Among these, labor cost variance by cost code is often one of the most useful leading indicators. Because labor is a large and highly variable cost, early deviations at the cost-code level frequently signal broader performance issues if left unaddressed.

What's the biggest mistake contractors make with cost tracking?

One of the most common mistakes is prioritizing reporting and analytics tools before addressing the quality of the data feeding them. Many organizations invest in sophisticated job costing or project management systems while continuing to rely on manual timesheets, delayed entries, or reconstructed labor data.

When underlying time data is inconsistent or inaccurate, even well-designed systems produce reports that are difficult to trust and harder to act on. Improving data accuracy at the source, particularly labor time capture, strengthens every downstream cost tracking and reporting process. Without that foundation, additional software complexity rarely delivers better insight.

The Bottom Line on Construction Cost Tracking

Construction cost tracking ultimately depends on measurement. Costs cannot be managed reliably without accurate data, and labor costs cannot be measured consistently when time data is incomplete, delayed, or reconstructed after the fact.

Across projects and organizations, effective cost tracking follows a consistent hierarchy:

- Accurate time data: reliable labor measurement is the foundation

- Proper cost classification: organizing labor and expenses into meaningful categories

- Timely integration: cost data flowing automatically into downstream systems

- Analysis and insight: dashboards, reporting, and forecasting built on trusted inputs

- Action and adjustment: decisions made based on current, credible information

Many organizations invest heavily in reporting, analytics, and decision tools while underestimating how strongly those outcomes depend on the quality of the underlying time data. When the foundation is weak, downstream systems inherit that uncertainty.

Improving labor time accuracy at the point of work strengthens every layer above it. Once accurate time data is flowing consistently from the field, cost tracking systems become easier to trust, easier to act on, and far more effective at supporting financial control.

See how accurate time data transforms your construction project cost tracking.