The construction industry has always been the root of modern society’s blooming, but going through that process, it has faced the challenges of meeting the high expectations of transparency, efficiency, and sustainability. With the help of state-of-the-art construction technologies, many companies are revolutionizing their processes to meet the demands of modern clients while still maintaining a strong and trustworthy relationship with stakeholders. From AI-powered analytics to cloud-based project management tools and green building techniques, these new techniques offer construction firms the opportunity to strengthen their collaboration, accountability, and performance.

In this article, we will dive into the world of construction to show you the newest trends in construction technology of 2025, breaking down how you can face the industry’s challenges, like optimizing productivity and creating trust with your clients during all the stages of the construction lifecycle.

AI-Powered Predictive Analytics and Project Management

Artificial intelligence (AI) has passed from an emerging tool to an essential asset in a matter of years for any type of business, so for the construction industry. AI-powered predictive analytics is letting project managers analyze vast amounts of data—from historical project performance to current environmental conditions and labor availability. Having all of this information available helps teams improve not only their decision-making but also their reliability, which helps boost client confidence.

How AI is Changing Construction Planning and Risk Management

AI has changed the way project managers develop construction planning in several important ways:

- Improving Schedule Accuracy: Advanced AI algorithms analyze past project data, pointing out common mistakes that used to impact timelines, like regional labor shortages or supply chain constraints. By taking into account all these factors, AI offers more accurate scheduling and mitigates unexpected delays.

- AI provides more up-to-date schedules and Dynamic Cost Forecasting: AI-powered models can be more precise in order to cut down on budgets more dynamically based on fluctuating material costs and economic factors, allowing teams to stay posted and be able to react on time in terms of inflation.

- Risk Scoring and Mitigation: By giving risk scores to all the elements in a construction project, AI helps managers face potential high-risk tasks, which leads to creating a more stable project environment and minimizing disruptions.

Case Study: AI-Driven Scheduling Reduces Delays by 30%

For example, we will show you how Turner Construction’s utilization of AI for the Hudson Yards project in New York helped reduce delays. By introducing AI in their scheduling system with its predictive analytics, the team was able to identify bottlenecks earlier than they used to and even before they impacted the timeline. The same goes for supply shortages. When Turner detected a possible delay in some materials with high demand, the AI system adjusted timelines, ordered replacement materials, and made sure the stakeholders were up-to-date with everything, making sure the deadlines were met. Click here to deepen your understanding of this topic.

Client Confidence Through Data-Driven Precision

Working with data-backed insights, the project schedules end up being more accurate whilst clients gain confidence in project timelines and budgets, as they know AI is constantly monitoring, adjusting, and optimizing all the elements so they can prevent unexpected changes. This transparency improves trust, as they can demonstrate commitment to predictability and accuracy, reducing client anxieties over potential schedule disruptions.

Cloud-Based Construction Software for Real-Time Collaboration

Cloud-based construction management platforms collect all the information of the project’s workflow in a single place, making it possible for stakeholders, from contractors to clients, to check out the project’s outcome in real-time. This up-to-date accessibility breaks down traditional communication barriers and improves collaboration across various stages of the project.

Key Benefits of Cloud Platforms

- Centralized Document Management: Having all the documents (blueprints, contracts, regulatory documents, inspection reports…)in the same place helps the project manager to save time and be prepared in any case of audit or regulatory procedure. As everyone has access to the unique and updated version of each document, misunderstandings, and rework are almost erased from the project.

- Instant Change Tracking and Notification: On construction sites, changes are inevitable. Cloud-based platforms allow teams to update plans in real time and instantly notify relevant stakeholders, ensuring that everyone, whether on-site or off, is aligned.

- 24/7 Client Access: Many cloud platforms also provide client portals where clients can log in, view live updates, access reports, and monitor project progress, empowering them to stay engaged without needing to be physically present.

Example: Panama Canal Expansion’s Cloud Collaboration Success

The Panama Canal expansion is a prime example of the power of cloud-based collaboration. By implementing a cloud platform, engineers, contractors, and project managers from multiple countries could share insights, review documents, and coordinate in real-time, mitigating misunderstandings and vastly reducing delays. This complex, international project showcased how cloud solutions provide a collaborative backbone, especially when dealing with large, geographically diverse teams.

Building Client Trust Through Transparency and Accessibility

For clients, being able to access project status at any time is a major trust-builder. They can see the updates, understand why adjustments were made, and anticipate any changes to timelines. This transparency eliminates surprises and reassures clients that they’re actively involved in a well-coordinated process.

Green Construction Technology for Sustainable Building

As the years have gone by, sustainability has emerged as a top priority across all industries, including construction. With the rise of green construction technology, companies are adapting their work to environmentally friendly practices. This shift not only reduces their ecological footprint but also creates lasting value for their clients. Nowadays, clients are more aware of climate change, so green building techniques have started to be advantageous and even expected.

Green Construction Practices that Drive Efficiency

- Sustainable Materials and Low-Carbon Concrete: The use of environmentally friendly materials like concrete with low-carbon emissions, recycled metal, and sustainably grown wood, companies can significantly cut down on their carbon footprint.

- Energy-Efficient Designs and Smart Systems: Project managers have recently started to count on energy-efficient systems, such as photovoltaic panels, smart lighting devices, and automatically regulated HVAC to reduce their ecological footprint. These devices can reduce costs and help get sustainable building certifications, appealing to the most aware clients.

- Water Recycling and Conservation Systems: By implementing water recycling systems, especially in large projects, construction firms can reduce consumption. Water is repurposed on-site for various uses, decreasing dependency on local water sources.

Hudson Yards: Pioneering Sustainable Urban Development

Hudson Yards in New York City stands as a landmark of sustainable development. It employs green roofs, district-wide energy management, and water recycling systems, reducing resource consumption. With the implementation of these systems, Hudson Yards met regulatory standards while setting a precedent for sustainable, energy-efficient urban spaces.

Get Control of Your Time Tracking

Wearable Technology for Enhanced Safety and Real-Time Monitoring

In the harsh environment of the construction industry, safety is still a critical concern. With wearable technology, project managers are able to monitor and protect workers on-site. These new wearable technologies, such as sensor vests, smart helmets, and augmented reality glasses, make real-time monitoring possible to jobsite managers, letting them be more reactive and cautious in case of any incident or unsafe practice.

Notable Wearable Technologies in Construction

- Smart Helmets for Hazard Detection: There is a new generation of helms, which, equipped with sensors, is capable of detecting hazards such as heavy machinery approaching or structural instability. It alerts the worker immediately, allowing the worker to avoid danger.

- Sensor Vests for Health Monitoring: With all kinds of sensors that can monitor heart rate, body temperature, and proximity to dangerous areas, wearable vests provide vital data to the worker and the project manager to prevent accidents due to physical strain or fatigue.

- Exoskeletons for Physical Support: These devices could help in projects that require heavy lifting, liberating the worker from great strains, reducing injuries, and repetitive transport of heavy loads.

Example: Texas Construction Site Reduces Accidents with Wearable Sensors

On a large project in Texas, the deployment of wearable technology helps to reduce accidents, most of them related to heat-related injuries. By tracking workers’ stress and fatigue levels, managers adjusted break schedules and distributed workloads more evenly. This data-driven approach to safety demonstrates a proactive commitment to worker wellbeing.

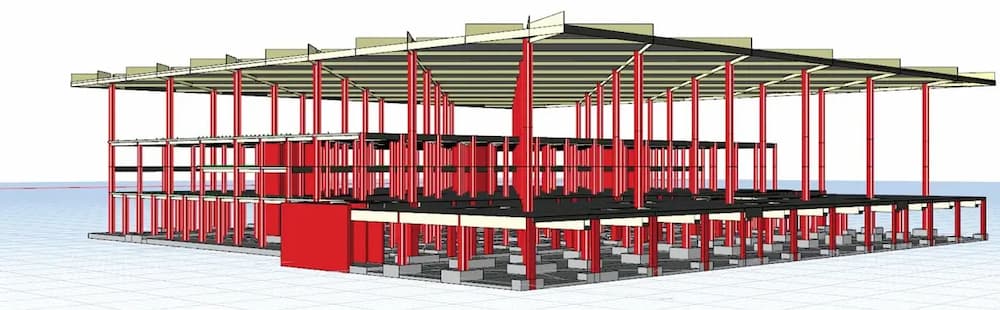

Building Information Modeling (BIM) for Precision and Collaboration

Building Information Modeling (BIM) has changed the way projects are conceived. Now, thanks to BIM, all the members of the project team can work collaboratively with the same 3D view of the construction lifecycle. You can combine the architecture, structural engineering, and mechanical systems in a single multidimensional model. By using it, there will not be miscommunication as frequently as there is nowadays.

Advantages of BIM in Project Coordination

- Error Prevention and Quality Control: With BIM, you can easily identify conflicts in design, such as elements clashing in a single space, which can be missed in 2D design, preventing going over the design twice.

- Efficient Communication and Visualization: Having a 3D visual format lets stakeholders explore the project even before starting construction, which can leave space for their comments and help reduce misunderstandings.

- Material and Time Efficiency: BIM takes into account all of the material requirements and manpower needed, which helps construction project managers adjust the budget better and reduce waste.

Example: Istanbul’s New Airport Built with BIM Precision

The new Istanbul Airport used BIM to coordinate its complex design, allowing architects, engineers, and contractors to identify and resolve design conflicts digitally before construction. This led to significant time savings and enhanced project alignment, demonstrating BIM’s capability to handle large, multifaceted projects.

Internet of Things (IoT) for Connected Construction Sites

The Internet of Things (IoT) is helping to transition from traditional construction job sites into connected ecosystems where machinery, equipment, and materials are in real-time communication non-stop. IoT keeps track of all the connected devices, giving project managers useful information such as location, usage, maintenance needs, and even environmental conditions.

IoT Applications that Enhance Efficiency and Safety

- Equipment Tracking and Maintenance Alerts: IoT can track the exact location of high-value machinery, reducing and preventing possible losses and making sure that there is an efficient deployment on-site. Sensors can also monitor the machine’s health and schedule maintenance, reducing the time that the workers cannot use them.

- Environmental Monitoring for Optimal Working Conditions: IoT sensors can track different conditions, from humidity and temperature to dust levels. Thanks to this, managers are aware of whether the conditions exceed safe thresholds.

- Material Inventory and Supply Chain Tracking: Putting sensors on materials enables real-time tracking from supplier to site, helping not to lose or damage any component and ensuring accurate inventory levels.

Example: Smart Sites at a Major Infrastructure Project in Dubai

In Dubai, IoT sensors are already being used on construction sites. They are used to track equipment and manage inventory. Real-time data helped reduce equipment downtime by 20% and minimized material losses, which is a direct improvement to project timelines and reduced costs.

Automation and Robotics for Efficiency and Precision

Automation and robotics are revolutionizing how construction tasks are performed, from robotic bricklaying to drone-based site surveys. Using these technologies improves the efficiency, speed, and accuracy of any task while minimizing delays and errors. This is a good way to add to your client’s confidence in the project’s quality and reliability.

Robotic Solutions in Construction

- Drones for Site Surveys and Progress Monitoring: Drones capture aerial footage. This gives important information in order to have more accurate and quicker land surveys and project monitoring.

- Robotic Bricklaying and Concrete Dispensing: Robots lay bricks and pour concrete with a level of precision that you couldn’t manually do, not even with many years of experience. This minimizes material waste, speeds up the process, and ensures quality.

- 3D Printing for Modular Components: 3D printers create walls, panels, and entire houses in a fraction of the time required by traditional methods. This technology is already being used in some specific cases but will be very common in the near future.

Case Study: Robotic Bricklaying Speeds Up Construction in High-Rise Projects

In Melbourne, a high-rise construction project utilized robotic bricklaying, reducing material waste by 20% and cutting completion time by half. This example illustrates how automation enhances quality while saving time and cost.

Automation’s Role in Building Client Trust

Automation improves consistency, reduces errors, and accelerates timelines, reinforcing client trust. Clients feel assured knowing that advanced precision technology is in place, demonstrating a commitment to quality and efficiency.

The Role of Technology in Building a Trustworthy Construction Industry

In 2025, construction technology fosters an industry grounded in transparency, efficiency, and trust. Tools like AI, BIM, cloud platforms, and green building methods empower firms to operate at high standards. SmartBarrel’s tech solutions help construction companies improve communication, enhance accuracy, and maintain safety standards. Embracing these technologies strengthens client trust and drives the industry toward a sustainable, collaborative future.

Ready to take your construction business to the next level? Discover how technological innovations can transform your projects, boost efficiency, and build trust with your clients. Schedule a demo with SmartBarrel today and start building the future of construction!