Accurate sizing of circuit breakers is crucial for balancing safety and efficiency in electrical installations. A circuit breaker, designed to automatically interrupt an electrical circuit to prevent excess current from causing damage, is a critical component in protecting electrical circuits and ensuring safety. Proper sizing ensures protection against overcurrent conditions while avoiding unnecessary tripping, helping in complying with the National Electrical Code (NEC), ensuring operational safety, and enhancing system efficiency.

Understanding Circuit Breaker Sizing

A circuit breaker sizing guide acts as a comprehensive resource for electrical sub-contractors. It aids in choosing the correct circuit breaker size for various applications, emphasizing:

- The importance of adhering to NEC requirements.

- Differentiating between continuous and non-continuous loads.

- Adjusting for ambient temperature variations.

In summary, mastering circuit breaker sizing involves understanding NEC compliance, differentiating between continuous and non-continuous loads, and adjusting for ambient temperature. This expertise not only ensures the longevity and reliability of electrical installations but also optimizes costs and maximizes safety and efficiency.

What is Circuit Breaker Sizing?

For electrical sub-contractors, circuit breaker sizing is a critical task that involves determining the correct size of a circuit breaker for specific electrical needs. This process is essential for balancing safety, efficiency, and regulatory compliance while minimizing costs and maximizing system reliability. Matching the right circuit breaker to a system’s requirements is akin to finding the perfect key for a lock—get it wrong, and you risk safety issues or inefficiencies in your electrical systems.

Circuit breakers are rated in amperes (A), indicating the maximum current they can handle without tripping. Choosing the correct size ensures they can manage the electrical load efficiently, avoiding unnecessary tripping or dangerous conditions. Achieving this balance is crucial for maintaining both safety and functionality in any electrical installation.

The role of the National Electrical Code (NEC) in circuit breaker sizing is pivotal. The NEC mandates that circuit breakers must be sized at 100% of non-continuous loads and 125% of continuous loads, a guideline that is crucial for electrical sub-contractors to understand and apply.

These requirements help accommodate the heat generated by electrical currents, thus preventing potential overheating and ensuring that each circuit breaker installed meets specific safety and performance thresholds.

The Importance of Accurate Circuit Breaker Sizing

Accurately sizing circuit breakers is foundational to electrical system design, ensuring safety, efficiency, and reliability. Here are the key reasons why precision in sizing is imperative:

- Safety First: Incorrectly sized circuit breakers can lead to fire hazards or equipment damage by either tripping too frequently or not tripping when needed.

- Efficiency and Reliability: Properly sized circuit breakers maintain electrical system performance, minimizing downtime and protecting components.

- Compliance: Following NEC guidelines ensures safety and helps avoid legal and financial repercussions.

Grasping the NEC’s intricate requirements for circuit breaker sizing is paramount for electrical sub-contractors. In this context, leveraging SmartBarrel’s construction management solutions can streamline compliance and enhance jobsite efficiency, presenting a significant advantage in the competitive construction landscape.

To ensure comprehensive coverage, this section will include detailed examples of how to calculate the appropriate size of circuit breakers for different types of loads, such as single-phase and three-phase supplies.

It will also discuss the impact of ambient temperature on circuit breaker performance and provide guidelines on adjusting for temperature variations. Incorporating statistical data on circuit breaker performance and safety records, alongside quotes from electrical safety organizations or leading industry experts, will substantiate the claims made in this section.

As we move forward, we’ll delve into the specifics of continuous and non-continuous loads and how these factors influence the selection process for circuit breakers. Highlighting practical examples and considerations, this guide will bring these concepts to life, demonstrating the critical role of accurate circuit breaker sizing in crafting safe, efficient, and reliable electrical systems.

Through a mix of technical details, industry insights, and SmartBarrel’s innovative solutions, electrical sub-contractors will find valuable guidance in navigating the complexities of circuit breaker sizing.

Prerequisites for Effective Sizing

Understanding NEC Requirements

The National Electrical Code (NEC) plays a pivotal role in ensuring safety in electrical installations. According to [source name](source URL), “The NEC’s primary goal is to protect people and property from electrical hazards through comprehensive guidelines.”

It sets the foundation for all circuit breaker sizing activities. Without adherence to NEC standards, safety and compliance are compromised.

To address the required depth, the section should be expanded to include:

- Detailed discussion on NEC regulations, citing specific articles such as Article 210 for branch circuits.

- Examples of calculations for sizing circuit breakers for single-phase and three-phase supplies.

- Discussion on the impact of ambient temperature on circuit breaker performance, with adjustments for temperature variations.

- Considerations for selecting circuit breakers in IT systems, including the implications of short-circuit current levels on circuit breaker selection.

This expansion should include statistical data and quotes from credible sources to substantiate the claims made.

Identifying Load Types

Key to effective circuit breaker sizing is distinguishing between continuous and non-continuous loads. The NEC defines a continuous load as one where the maximum current is expected to continue for three hours or more, such as office lighting. This distinction is crucial because it directly influences how circuit breakers are sized:

- Continuous Loads: For these, the NEC mandates that circuit breakers must be sized at least 125% of the continuous load. This accounts for the additional heat generated over prolonged periods.

- Non-Continuous Loads: These do not have the same duration or heat generation concerns. Circuit breakers can be sized to 100% of non-continuous load values.

Understanding this difference is vital. It ensures that every circuit breaker can handle its load without being overtaxed or triggering unnecessarily.

Proper sizing for both load types enhances system reliability and safety, preventing overloads and minimizing downtime.

To illustrate, consider an office building with extensive lighting systems operating for more than three hours daily. These systems represent a continuous load and require circuit breakers sized at 125% of their maximum current draw.

On the other hand, a drill press in a workshop, used intermittently, exemplifies a non-continuous load, requiring a breaker sized accordingly.

By accurately identifying and categorizing loads, electrical sub-contractors can tailor their approach to circuit breaker sizing. This precision not only aligns with NEC requirements but also ensures that electrical systems are both safe and efficient.

As we transition into the next part of our circuit breaker sizing guide, focusing on the NEC, continuous load, and non-continuous load, we will explore practical tools and techniques for calculating load requirements. This part of our circuit breaker sizing guide will equip electrical sub-contractors with the knowledge they need to ensure safety, efficiency, and compliance in their projects.

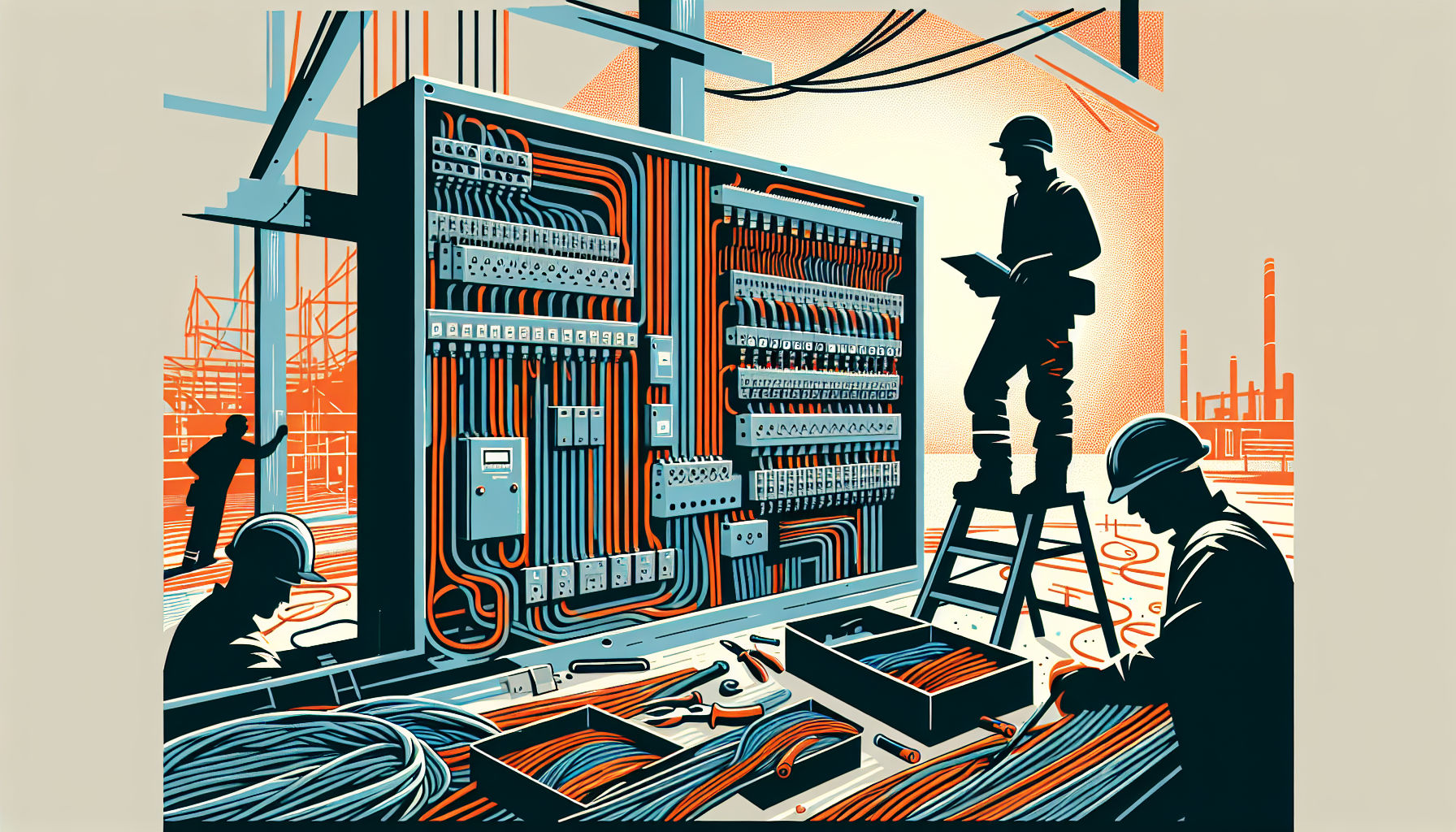

How to Size Circuit Breakers Accurately

Step 1: Determine Load Type and Magnitude

Understanding the nature and scale of the electrical load is the cornerstone of accurate circuit breaker sizing. Both continuous and non-continuous loads must be considered:

- Continuous loads are those expected to run at maximum capacity for three hours or more. According to the NEC, they require a circuit breaker sized at 125% of the load to handle the generated heat over time. For instance, a continuous load drawing 50A mandates a circuit breaker with a minimum rating of 62.5A.

- Non-continuous loads, on the other hand, do not have the same prolonged operation. They can be matched directly to their maximum current draw without the additional percentage. A 300A non-continuous load, therefore, can be served by a 300A circuit breaker.

Highlighting the importance of distinguishing between these load types ensures proper circuit protection and system efficiency.

Step 2: Apply NEC Guidelines

The National Electrical Code (NEC) provides a comprehensive framework for determining the minimum size of circuit breakers required for both continuous and non-continuous loads, ensuring compliance and safety in electrical installations.

- For continuous loads, the NEC’s stipulation to size circuit breakers at 125% of the load aims to accommodate additional heat generation. This preemptive measure aids in preventing overheating and potential system damage.

- Non-continuous loads are governed less stringently, allowing circuit breakers to be sized exactly according to the load’s peak demand.

By adhering to these guidelines, we not only follow a code-compliant path but also craft installations poised for longevity and reliability.

Step 3: Adjust for Ambient Temperature

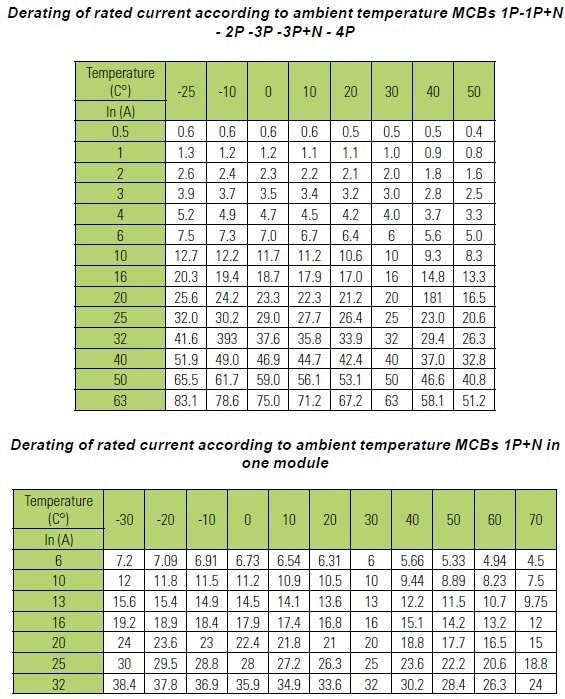

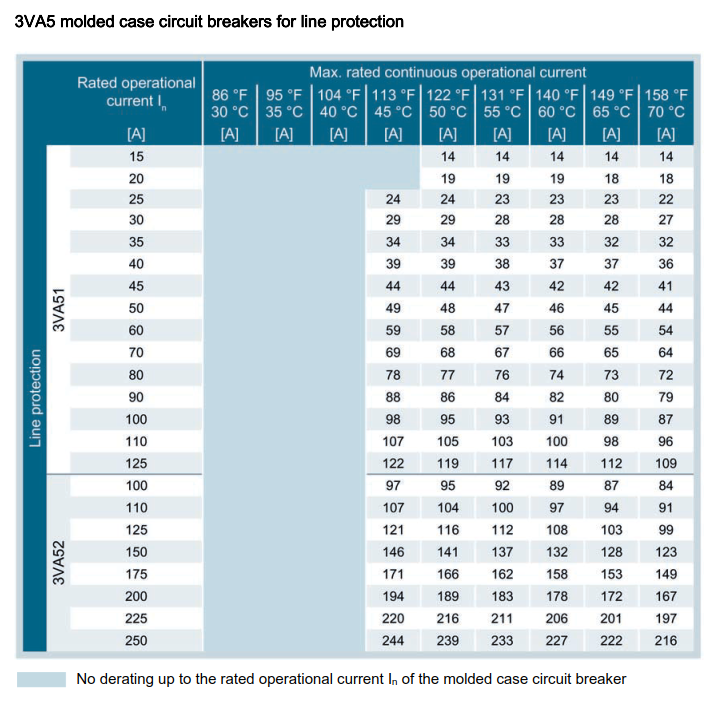

Circuit breaker performance is sensitive to ambient temperature conditions, as demonstrated in our analysis.

Furthermore,

provides additional insights into how ambient temperature impacts the derating of circuit breakers, emphasizing the need for careful selection based on environmental conditions.

Ambient temperature outside of the standard operating range (typically around 30°C) can significantly affect a breaker’s ability to carry current. As temperatures rise, breakers must be derated; that is, chosen with a higher current rating to maintain functionality without nuisance tripping.

Step 4: Consider Special Requirements for IT Systems

IT systems often have unique electrical needs, including considerations for double earth faults. It’s crucial to account for these when sizing circuit breakers, ensuring uninterrupted operation and protection against potential issues specific to these systems.

Step 5: Evaluate Short-circuit Current Levels

Assessing the potential short-circuit current levels is an indispensable part of selecting an appropriate circuit breaker. This entails calculating the highest current that can flow through a system during a short-circuit condition and ensuring the chosen breaker can interrupt this current safely.

The necessity of sizing breakers correctly becomes apparent with the awareness that choosing a breaker with an adequate interrupting rating prevents equipment damage and enhances overall safety.

By following this detailed circuit breaker sizing guide, electrical sub-contractors can adeptly navigate the complexities of properly sizing circuit breakers, ensuring safety and efficiency on their projects.

This nuanced approach—considering load types, adhering to NEC standards, adjusting for ambient conditions, addressing special system requirements, and evaluating short-circuit potentials—heralds safe, compliant, and efficient electrical installations.

Transitioning from these technical considerations, it’s equally essential to understand common pitfalls in circuit breaker sizing and how to avoid them.

This insight will further empower contractors to make informed decisions, steering clear of costly errors and enhancing project outcomes.

NEC Requirements Deep Dive

In the realm of circuit breaker sizing, the National Electrical Code (NEC), particularly Articles 210, 215, and 240, serves as the definitive guide. Its regulations are designed to ensure safety and efficiency in electrical installations. A closer look at specific NEC articles unveils a complex landscape that electrical sub-contractors must navigate with precision.

Detailing NEC Articles

The NEC’s influence on circuit breaker sizing is evident through its meticulous requirements, such as calculating a 125% increase for continuous loads and considering the peak load for noncontinuous loads, which are crucial for both single-phase and three-phase supplies.

According to EC&M, the 1996 NEC recognizes that overcurrent protective devices will be affected by heat in the system, highlighting the importance of understanding continuous loads and the 80% rule to mitigate the effects of heat within a system. The NEC defines continuous loads as those where the maximum current continues for three hours or more, like office lighting.

It mandates that the size of the overcurrent protective device (OCPD) should accommodate 100% of noncontinuous loads plus 125% of continuous loads.

Additionally, EE Power elaborates on NEC® Article 210, which establishes branch-circuit conductor sizing and protection. This piece of the NEC puzzle requires that the ampacity of minimum branch-circuit conductors not be less than the noncontinuous load plus 125% of the continuous load. This ensures conductors withstand both types of loads effectively after considering factors like ambient temperature corrections.

Furthermore, the NEC guides the selection of circuit breakers in IT systems, emphasizing the need for breakers tested according to Annex H of IEC60947-2 for proper breaking capacity in double earth fault situations.

Moreover, the role and application of dual-function breakers are clarified within the NEC, as per CircuitIQ. These breakers merge GFCI and AFCI protections into a cost-effective solution that addresses multiple safety concerns in specific locations such as kitchens.

Real-world Applications

Understanding these NEC articles is one thing; applying them to real-world scenarios is another. Take, for example, an office building’s lighting system classified as a continuous load. According to NEC requirements, if this system draws 50A, a circuit breaker must be sized at 125% of this load, resulting in a 62.5A requirement.

The guidance suggests opting for a 200A OCPD to ensure safety and compliance.

For noncontinuous loads, such as machinery used intermittently in a factory setting, the NEC permits sizing the breaker equivalent to the peak load demand. If such machinery draws a 300A noncontinuous load, a 300A device suffices without necessitating a 100%-rated device.

The insights provided by sources like Electrical Technology, which states that “proper circuit breaker sizing is essential for safe electrical installations,” and Mike Holt Enterprises reinforce the significance of selecting circuit breakers that align closely with NEC standards. This adherence not only promotes safety but also ensures operational efficiency and reliability across various installations.

Understanding and applying these nuanced NEC guidelines empower contractors to execute projects that stand up to regulatory scrutiny while ensuring maximal safety and functionality. As we advance into potential pitfalls in circuit breaker sizing and ways to sidestep them, remembering these deep dives into NEC requirements will serve as a foundation for making informed decisions that elevate the quality and compliance of electrical installations.

Circuit Breaker Sizing Guide: Managing Continuous vs. Non-continuous Loads

Understanding the NEC’s definition of continuous and non-continuous loads is crucial for accurate circuit breaker sizing, ensuring installations are safe and compliant with regulations. Let’s delve into strategies for accurately accounting for these load types, integrating SmartBarrel’s solutions, and illustrate the approach with calculation examples.

Accounting for Continuous Loads

Continuous loads require a circuit breaker sized at 125% of the load to accommodate the additional heat generated over time. This means:

Consider a load that draws 40A continuously. In this case, the circuit breaker should be rated for at least 50A, calculated as 40A multiplied by 125%.

This sizing is crucial to prevent overheating and potential damage to the electrical system.

According to EE Power, it’s vital to apply ambient temperature correction factors and adjustment factors for more than three current-carrying conductors in a raceway or cable. These adjustments ensure that the conductors can withstand 100% of the non-continuous load plus 100% of the continuous load after applying these factors.

Accounting for Non-continuous Loads

For non-continuous loads, where the maximum current does not continue for three hours or more, circuit breakers can be sized according to the maximum load served. To ensure system reliability, remember the following key points:

- The ampacity of circuit conductors must not be less than the non-continuous load plus 125% of the continuous load.

- Applying these guidelines prevents unnecessary tripping and ensures the system can handle demand spikes.

It’s also imperative to consider that the temperature rating related to the ampacity of a conductor must not exceed the lowest temperature rating of any connected termination, conductor, or device as highlighted by EE Power.

Example Calculation:

- An electrical panel has a continuous load of 20A and a non-continuous load of 30A.

- First, calculate the continuous load portion: 20A x 125% = 25A.

- Then, add the non-continuous load: 25A + 30A = 55A.

Thus, a circuit breaker rated at least 55A is necessary to safely manage this combination of loads, taking into account both continuous and non-continuous demands on the system.

By distinguishing between continuous and non-continuous loads and applying the NEC’s guidelines, electrical sub-contractors can ensure their installations are both safe and efficient. Utilizing SmartBarrel’s construction management solutions can further enhance jobsite safety and efficiency. Understanding how to accurately size circuit breakers using these principles protects against overloads, avoids unnecessary tripping, and maximizes the longevity of electrical systems.

Transitioning now, let’s move on to explore common pitfalls in circuit breaker sizing and effective strategies to avoid them. This will further enhance our ability to select appropriate protective devices for various electrical installations.

Impact of Ambient Temperature on Performance

Understanding how ambient temperature affects circuit breaker performance is essential. Circuit breakers are designed to carry 100% of their rated current, but this capability can decrease in higher temperatures. The NEC dictates utilizing circuit breakers at 80% capacity for certain applications, considering the effects of temperature.

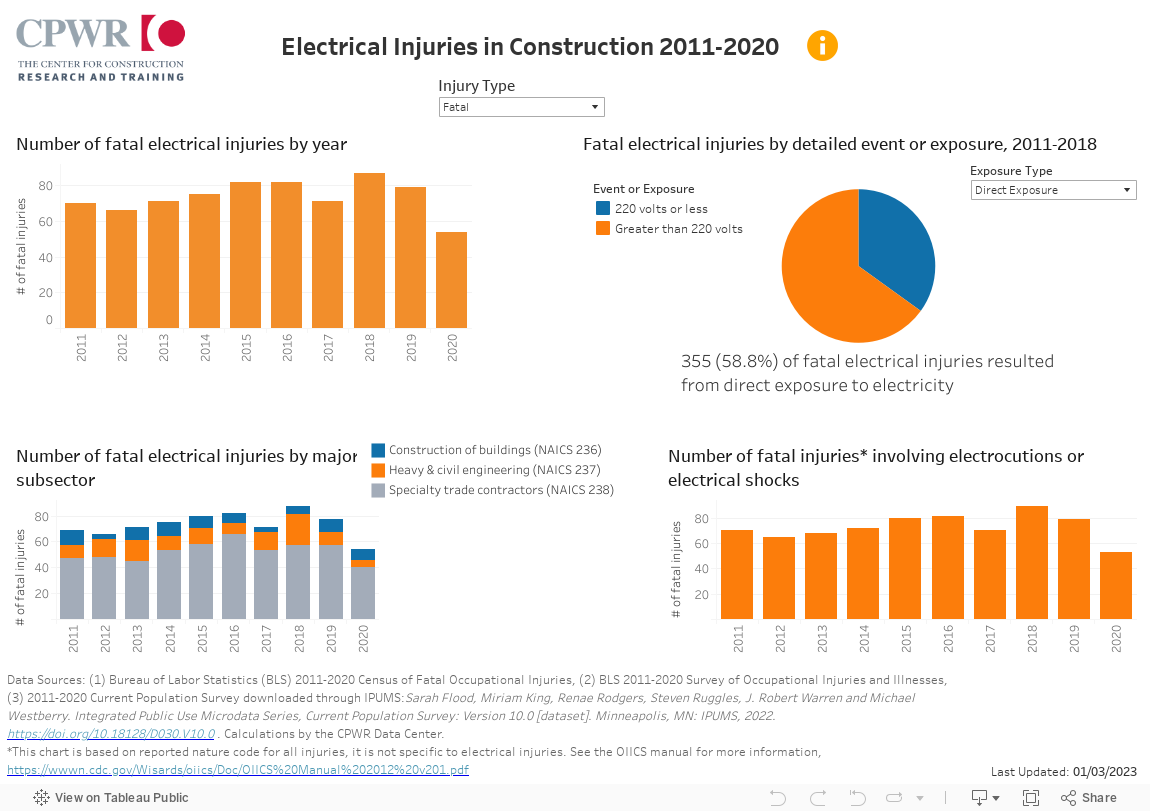

The CPWR data on electrical injuries underscores the importance of adhering to safety protocols, including accurate circuit breaker sizing, to prevent fatal incidents.

The ESFI statistics on workplace electrical fatalities highlight the need for comprehensive safety knowledge and proper circuit breaker sizing across various job roles.

To accurately size circuit breakers, it’s crucial to understand NEC regulations that dictate the use of circuit breakers at 80% capacity for continuous loads, ensuring safety and compliance.

For non-continuous loads, the breaker can be sized closer to the actual load, offering cost savings without compromising safety. Calculating the appropriate size involves understanding the load’s nature and applying formulas for single-phase and three-phase supplies, adjusting for factors like ambient temperature.

This section serves as a circuit breaker sizing guide, offering insights into the impact of ambient temperature on performance and practical tips for compensating for temperature differences.

The Science Behind Temperature’s Effect on Circuit Breakers

The functionality of circuit breakers is influenced by ambient temperature. At higher temperatures, the metal components within a breaker expand, potentially affecting the breaker’s ability to conduct electricity and trip in an overload situation. As a result, breakers may need to be derated, meaning selected with a higher rating than the calculated load requires, to compensate for the loss in performance due to heat.

- Ambient temperature increases can lead to a notable reduction in a circuit breaker’s efficiency in handling current. Derating is a strategic response, ensuring protection remains robust.

- Derating a circuit breaker ensures that it can still protect the circuit even if its performance dips due to high temperatures.

This consideration is crucial for installations in environments that experience significant temperature variations.

Practical Tips for Compensating for Temperature Differences

When dealing with circuit breaker installations in areas subject to high ambient temperatures or fluctuations, several practical steps can be taken:

- Derating Breakers: By selecting a breaker with a higher current rating than the load calculation suggests, we offset potential performance dips due to heat. This foresight safeguards the circuit.

- Installation Location: Thoughtful placement of circuit breakers can mitigate temperature extremes. Avoiding direct sunlight and proximity to heat sources is wise.

- Ventilation: A well-ventilated area around the breaker panel promotes a stable temperature environment, crucial for optimal performance.

By implementing these strategies, electrical sub-contractors can enhance system reliability and safety. It’s a proactive approach to dealing with potential temperature-related issues that could compromise circuit breaker performance.

The principle of derating circuit breakers in response to ambient temperature variations is a critical consideration in electrical engineering. According to industry experts, “Ambient temperature can significantly impact the performance of circuit breakers, necessitating adjustments in their sizing to ensure reliability and safety in electrical installations.” This approach is essential for maintaining system integrity across various applications.

SmartBarrel offers solutions that can help manage the complexities of circuit breaker sizing and installation, ensuring compliance with safety standards and enhancing jobsite efficiency. By leveraging SmartBarrel’s construction management solutions, electrical subcontractors can streamline their operations, focusing on safety and efficiency.

As we move forward, it’s important to keep in mind the impact that ambient temperature can have on circuit breaker operation. Making informed choices about derating, installation location, and ensuring proper ventilation can help mitigate these effects.

With a solid understanding of these concepts, we’re better equipped to tackle the challenges of accurately sizing circuit breakers for various applications.

In the next section, we’ll delve into common pitfalls in circuit breaker sizing and offer effective strategies to navigate these challenges. This knowledge will further empower you to make informed decisions in your project planning and execution stages.

Selecting Circuit Breakers for IT Systems

Determining the right circuit breaker for IT systems presents unique challenges, necessitating a comprehensive circuit breaker sizing guide. The critical need for uninterrupted power and the complexity of fault scenarios, such as double earth faults, underscore this requirement.

Unique Challenges in Sizing Breakers for IT Systems

IT systems are vital for many businesses, requiring a continuous power supply. Any disruption risks data loss and equipment damage, making correct circuit breaker selection crucial.

One such peculiarity is the occurrence of double earth faults. These faults can be particularly problematic as they might not trigger a standard circuit breaker into action, leading to potential equipment damage or even fire hazards. This underscores the need for a thorough understanding and careful consideration when sizing circuit breakers for IT environments.

Considerations for Double Earth Faults

Double earth faults pose a significant risk in IT systems. They occur when two different points in an electrical system simultaneously come into contact with the earth, potentially bypassing the protection mechanisms of standard circuit breakers. This situation demands special attention:

- Dual function breakers integrate both GFCI (Ground Fault Circuit Interrupter) and AFCI (Arc Fault Circuit Interrupter) protections. These are indispensable in mitigating risks associated with double earth faults.

- According to CircuitIQ, understanding electrical codes regarding AFCI and GFCI protection is crucial for the proper use of dual function breakers. These breakers monitor for series and parallel arc faults, as well as ground faults, offering a comprehensive safety mechanism.

- The integration of GFCI and AFCI functionalities into a single solution, as seen in dual function breakers, ensures both ground fault and arc fault protection. This integrated approach is essential for safeguarding IT systems against both conventional and unique electrical faults.

For locations like IT server rooms, it’s advised to safeguard all circuits with arc fault protection while also addressing GFCI needs using a dual-function breaker. This setup streamlines the safety mechanism, ensuring comprehensive protection.

To enhance IT systems’ security and overall construction site safety through technology, consider exploring SmartBarrel’s solutions.

Next, we’ll explore common pitfalls in circuit breaker selection for various applications and provide strategies to avoid them.

Understanding Short-circuit Current Levels

Calculating and considering short-circuit currents is crucial in circuit breaker sizing. This ensures safety and compliance. Protecting both the electrical system and connected devices from potential harm. Understanding the implications of short-circuit current levels allows for more precise breaker selection. This directly impacts the reliability and efficiency of the installation.

The Importance of Calculating Short-circuit Currents

Short-circuit currents pose a significant risk to electrical systems. They occur when an accidental path of low resistance is introduced, allowing a high volume of current to flow through the circuit. This unexpected influx can cause severe damage to equipment and increase the risk of fire.

Accurately calculating potential short-circuit currents is essential. It helps in choosing a circuit breaker capable of interrupting these currents without sustaining damage.

Factors Influencing Short-circuit Current Levels

Several factors can influence the level of short-circuit current in a system:

- System voltage: The higher the voltage, the higher the potential short-circuit current.

- Impedance of the circuit: This includes the resistance and reactance of the components within the circuit. Lower impedance results in higher short-circuit currents.

- Distance from the source: The closer the point of fault is to the source of power, the higher the short-circuit current tends to be.

Taking these factors into account is vital. It ensures that all potential risks are considered when performing calculations.

Incorporating Short-circuit Currents into Breaker Sizing

To safeguard against short-circuit currents, it’s essential to select a circuit breaker size 20-25% higher than the flowing current in the cables and wires to the connected device. This step is crucial for safety and compliance.

According to Electrical Technology, a circuit breaker is designed to carry 100% of its rated current. However, the NEC dictates an 80% application. This guideline suggests adopting a circuit breaker size 20-25% larger than the current flow. It provides a buffer that accounts for unexpected high-current scenarios, including short-circuits.

For example, if calculations indicate a flowing current of 80A in a system, selecting a circuit breaker rated for at least 100-125A would be prudent. This approach accommodates for short-circuit conditions. It ensures that the breaker can handle sudden surges without tripping unnecessarily or failing to trip at all.

Remember, proper sizing of circuit breakers involves not only meeting immediate operational needs but also anticipating exceptional conditions like short-circuits. By incorporating calculations for short-circuit current levels into your sizing considerations, you lay a foundation for safer, more reliable electrical installations.

In conclusion, incorporating short-circuit current considerations into circuit breaker sizing is vital for ensuring safety and operational efficiency.

SmartBarrel’s construction management solutions can help manage the complexities of electrical installations, ensuring safety, efficiency, and compliance with regulations.

Moving forward, we will delve into how to practically apply these concepts in real-world settings. Our projects remain safe, compliant, and cost-efficient, with SmartBarrel’s solutions enhancing our approach to circuit breaker sizing and electrical installations.

Conclusion

In the intricate world of electrical installations, precision in circuit breaker sizing cannot be understated. This guide has traversed the essential territories—from understanding the critical distinctions between load types to meticulously adhering to NEC guidelines. Here’s a succinct wrap-up:

- Recap of Critical Steps:

- Determine load type and magnitude, considering both continuous and non-continuous loads.

- Apply NEC guidelines to align with safety codes and efficiency standards.

- Adjust for ambient temperature effects on breaker performance.

- Account for special requirements, particularly in IT systems.

- Evaluate short-circuit current levels to ensure robust protection.

NEC Compliance: Adherence to NEC standards is pivotal. It’s not just about meeting legal requirements; it’s about ensuring the safety and efficiency of your electrical installations. The electrical industry is poised for continued advancements in circuit breaker technology, making adherence to NEC guidelines even more crucial. These guidelines ensure installations are not only compliant but also prepared to embrace evolving technologies effectively.

Encouragement to Apply Principles: Applying these principles transcends regulatory compliance; it propels project success. By integrating this knowledge into your projects, you stand to enhance system reliability, ensure safety, and optimize operational efficiency.

Incorporating this circuit breaker sizing guide into your projects, much like Related Urban Construction did by adopting SmartBarrel for enhanced compliance and efficiency, equips you to tackle complex electrical installations with confidence. Learn more from their experience here.

Enhancing project management prowess extends beyond accurate circuit breaker sizing. SmartBarrel’s Construction Cost & Productivity Tracking Software complements these principles, offering tools that boost jobsite efficiency, safety, and compliance. Explore these tools to set your projects up for unparalleled success.