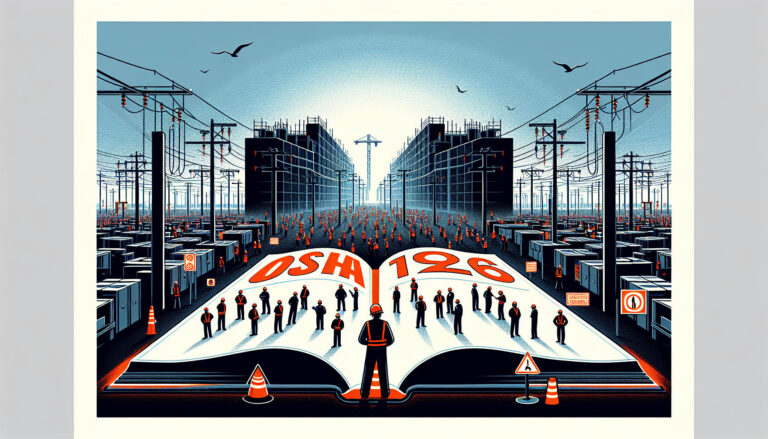

Understanding the OSHA 1926 electrical standards is crucial for electrical subcontractors. These regulations, specifically designed for the construction industry, are pivotal in ensuring construction safety and health on job sites.

The scope of these standards is broad, covering various safety topics across 27 subparts, including personal protective equipment, fire protection, and electrical safety.

For electrical subcontractors, deciphering and implementing these standards is not just about legal compliance—it’s about ensuring construction safety and the well-being of every worker involved in a project.

Achieving compliance with OSHA 1926 electrical standards is paramount. It’s not just about avoiding legal penalties; it’s about providing a work environment that is safe, sanitary, and not hazardous to the health and safety of employees.

The importance of compliance cannot be overstated. Ensuring a safe work environment reduces the risk of accidents, enhances productivity, and upholds your reputation as a responsible employer.

“OSHA 1926 Standards: These are a set of regulations provided by the Occupational Safety and Health Administration (OSHA) specifically designed for the construction industry to ensure safety and health at construction sites. The standards cover a wide range of safety topics divided into 27 subparts, including but not limited to personal protective equipment, fire protection, electrical safety, and fall protection.”

“Laborers and mechanics must be provided with working conditions and surroundings that are sanitary, not hazardous, and not dangerous to the health and safety of employees engaged in the performance of said contract.” – OSHA 1926 Subpart B

Key Takeaways

In this overview, we aim to demystify the OSHA 1926 standards related to electrical safety in construction.

- A thorough breakdown of OSHA 1926 standards.

- Essential steps for achieving compliance and implementing effective safety measures.

- The critical role of training and personal protective equipment (PPE) in maintaining a safe workplace.

By focusing on these areas, we strive to equip you with the knowledge needed to navigate the complexities of OSHA 1926 electrical standards effectively. This understanding will not only aid in enhancing workplace safety but also in avoiding potential penalties for non-compliance.

For more detailed information about preventing workplace accidents, our article on how to prevent construction hazards on your job site provides practical advice. This resource complements the importance of understanding and complying with OSHA 1926 standards for safety. By the end of this overview, you will be better prepared to undertake the necessary steps to ensure a secure and compliant work environment for all your construction projects.

Understanding OSHA 1926 Electrical

OSHA 1926 electrical standards, divided into 27 subparts focusing on various aspects of construction safety, form the backbone of construction safety. Specifically, Subpart K provides crucial guidelines for managing electrical hazards on construction sites. Imagine these standards as the rules of the road for construction electrical safety.

Just as traffic laws prevent accidents on the road, OSHA 1926 standards are designed to prevent workplace accidents and ensure safety.

Simplifying the Technical Jargon

Subparts in OSHA 1926Subpart K

Subpart K, then, is the chapter that lays out the rules for handling electricity safely on the construction site.

Why OSHA 1926 Electrical Standards Matter

The importance of adhering to these standards cannot be overstated. They are lifelines preventing dangerous or even fatal accidents on job sites.

- Preventing Workplace Accidents: Electrical hazards can lead to serious accidents, including shocks, burns, and fires. Following OSHA 1926 guidelines helps minimize these risks.

- Ensuring Safety: Compliance with these standards creates a safer work environment, which in turn boosts worker confidence and productivity.

Understanding and managing the risks associated with electrical work is vital for construction safety. By adhering to OSHA 1926 electrical standards, contractors can significantly reduce the potential for electrical-related injuries or fatalities, enhancing construction safety.

In the next section, we’ll explore practical steps for achieving compliance with OSHA 1926 electrical standards, including how SmartBarrel’s construction management solutions can streamline this process. This includes how to implement effective safety measures, the role of training, and the importance of personal protective equipment (PPE) in maintaining a safe workplace.

Preparing for Compliance

Compliance with OSHA 1926 electrical standards is not just a legal requirement but a moral imperative to ensure the safety and well-being of every individual on a construction site. Preparing for compliance involves a systematic approach to assessing current safety practices and understanding the legal requirements.

Assessing Current Safety Practices

It’s crucial to evaluate your current safety protocols against OSHA 1926 standards. This process begins with a comprehensive safety audit.

- Conduct a safety audit: This entails examining all workplace practices, equipment, and employee behaviors to ensure they meet the required standards. It’s not just about checking boxes; it’s about identifying potential hazards and taking corrective action before they lead to accidents.

- Identify gaps in current practices: This step involves comparing your current safety measures with those outlined in OSHA 1926. Identifying these gaps is the first step toward rectification.

This stage sets the foundation for implementing necessary changes to enhance workplace safety.

To support this, SmartBarrel offers Construction Site Safety Management solutions, streamlining the audit process and identifying gaps in compliance.

Employers must initiate and maintain programs to ensure compliance with safety and health requirements, including frequent and regular inspections by competent persons.

Understanding Legal Requirements

The legal implications of OSHA 1926 electrical standards for electrical subcontractors are significant, emphasizing that compliance is not optional but enforceable.

Employers are responsible for ensuring that their worksites comply with these standards to provide a safe working environment, which includes initiating and maintaining programs for safety and health requirements.

Non-compliance can lead to severe penalties, including fines and legal action.

Compliance and Enforcement: OSHA 1926 standards are enforceable, and non-compliance can lead to penalties. Employers are responsible for ensuring that their worksites comply with these standards to provide a safe working environment.

- Interpret key sections relevant to electrical work: For electrical subcontractors, it’s crucial to understand not only Subpart K, which directly addresses electrical standards, but also how Subparts A (General Requirements), B (General Interpretations), and C (General Safety and Health Provisions) of OSHA 1926 electrical standards apply to electrical safety in construction. These sections collectively provide a comprehensive framework for safe work practices.

- Explain penalties for non-compliance: The consequences of failing to adhere to these standards are far-reaching. According to Industrial Compliance & Safety, non-compliance can lead to fines, legal repercussions, project delays, increased insurance premiums, and damage to a company’s reputation. Moreover, accidents resulting from non-compliance can cause severe injuries or fatalities, alongside increased costs associated with medical treatment and workers’ compensation.

Understanding these legal requirements is fundamental for electrical subcontractors to ensure compliance and maintain a safe work environment.

A practical example of this is seen in the case study of Related Urban Construction’s Compliance Management, where the transition from paper-based to digital attendance tracking and compliance reporting led to a significant reduction in compliance reporting time, improving efficiency and enhancing accuracy in payroll and compliance data. Read more about Related Urban Construction’s Compliance Management.

Transitioning into the next section, we’ll explore effective strategies for achieving compliance through training, personal protective equipment (PPE), and accident prevention techniques.

How to Ensure Compliance with OSHA 1926

Step 1: Conduct a Comprehensive Audit

Employers in the construction industry, including electrical subcontractors, have a significant responsibility to ensure their worksites comply with OSHA 1926 electrical standards. Conducting a comprehensive audit is the first step in this process, involving a detailed review of all existing safety measures against OSHA’s requirements. This includes ensuring employees have the necessary personal protective equipment to safely perform their duties.

- Guide on auditing current safety measures against OSHA standards:

- Review OSHA 1926 electrical guidelines carefully.

- Examine your workplace practices, equipment, and employee behaviors in detail.

- Identify any discrepancies between your current practices and what is required by OSHA.

- Importance of identifying discrepancies and planning corrective actions:

- Identifying gaps allows for the development of a targeted action plan.

- Corrective actions might include updating equipment, revising work practices, or enhancing safety protocols.

Employers have the responsibility to provide a safe workplace, including compliance with eCFR :: 29 CFR Part 1926 Subpart K — Electrical, which details the electrical safety requirements necessary for the practical safeguarding of employees in construction.

This includes installation safety requirements, safety-related work practices, and special equipment safety requirements. Failing to identify and address discrepancies can lead to accidents, injuries, and penalties.

Step 2: Implement Required Changes

After identifying areas for improvement, the next step is to implement the necessary changes.

- Detail the process of updating safety protocols and practices:

- Based on the audit findings, update or revise safety protocols to ensure alignment with OSHA 1926 electrical standards.

- Introduce new safety practices if gaps are identified, such as regular equipment inspections and maintenance.

- Emphasize the role of technology, like SmartBarrel, in simplifying compliance:

- Utilize technology solutions like SmartBarrel for real-time monitoring and management of safety practices.

- Technology can streamline compliance efforts, making it easier to track and rectify safety protocol discrepancies.

Implementing these changes, as demonstrated in the Prism Electric’s Time Tracking for Large Workforce and Juneau Construction’s Operational Upgrade case studies, showcases how technology like SmartBarrel can simplify compliance with safety standards.

These examples highlight efficient time tracking, integration with payroll systems, and operational efficiency gains, all contributing to a safer work environment.

Step 3: Train Employees on New Standards

Ensuring all team members are aware of the updated standards is crucial for maintaining a safe workplace.

- Outline the training process for employees on updated safety measures:

- Develop comprehensive training programs that cover all aspects of OSHA 1926 electrical compliance.

- Include practical demonstrations and hands-on training to ensure understanding and retention.

- Highlight the importance of ongoing education to maintain compliance:

- Continual training ensures that employees remain aware of best practices and regulatory updates.

- Regular refresher courses can help maintain a high level of safety awareness among workers.

Training requirements under OSHA 1926 electrical emphasize the need for employers to equip their workforce with the knowledge and skills necessary to safely perform their duties.

This not only helps in avoiding accidents but also ensures compliance with regulatory standards.

Step 4: Regularly Review and Update Safety Measures

To stay ahead in maintaining a safe work environment, it’s important to periodically review and update safety measures.

- Advise on setting up a schedule for regular safety reviews:

- Establish a routine schedule for reviewing and assessing all safety measures.

- These reviews should be conducted at least annually or following any significant project changes or incidents.

- Discuss the benefits of continuous improvement in safety practices:

- Continuous improvement leads to an evolving safety culture that can adapt to new challenges and regulations.

- It also demonstrates a commitment to safety that goes beyond compliance, benefiting everyone involved.

For insights into the benefits of continual improvement in construction safety practices, consider reading Keys to Continual Improvement in Construction. This resource aligns with the ongoing efforts needed to ensure worker safety and compliance.

As we conclude this section on achieving compliance with OSHA regulations, it’s clear that adhering to these standards is essential for creating a safe work environment.

The implementation of updated safety measures, alongside ongoing training and continuous review, positions us well for transitioning into a discussion on practical tips for accident prevention.

Conclusion

In the realm of construction, understanding the scope and applicability of OSHA 1926 electrical standards is crucial for ensuring safety and adherence to regulations. This is not just a legal formality—it’s a cornerstone of operational integrity and workforce protection for electrical subcontractors. The OSHA 1926 electrical standards serve as a fundamental guide for electrical subcontractors, delineating the protocols necessary for safeguarding against electrical hazards effectively.

Understanding the scope and applicability of these standards is crucial for electrical subcontractors to ensure compliance and maintain a safe work environment. This comprehensive overview underscores the pivotal role these standards play in not only fostering compliance but also championing a culture of safety within the construction industry.

Electrical subcontractors are encouraged to embrace a proactive stance towards compliance. This involves:

- Rigorous audits of current safety measures

- Implementation of requisite changes

- Comprehensive training on new standards

- Periodic review and enhancement of safety protocols

We strongly encourage electrical subcontractors to embrace a proactive stance towards compliance with OSHA 1926 electrical standards.

The incorporation of advanced technological solutions can significantly streamline this process. SmartBarrel, with its suite of innovative products, stands at the forefront of facilitating efficient compliance and safety management. Leveraging such technology ensures:

- An orchestrated approach to auditing and gap identification

- Simplified implementation of corrective actions

- Streamlined training processes

- Enhanced capability for regular safety reviews

For electrical subcontractors intent on navigating the complexities of OSHA 1926 electrical compliance effectively, adopting SmartBarrel’s technology could be a game-changer. A prime example is seen in the Kiewit’s Attendance Tracking Efficiency, where SmartBarrel’s technology facilitated real-time, accurate attendance tracking, leading to cost savings and improved emergency preparedness through accurate headcounts.

By infusing operations with intelligent solutions like Subcontractor Time Tracking, businesses can achieve unprecedented levels of efficiency, safety, and compliance.

In conclusion, mastering the intricacies of OSHA 1926 electrical standards is indispensable for ensuring construction safety and regulatory compliance. Achieving compliance is essential for maintaining a safe work environment in the construction industry. The pathway to achieving this involves not just understanding these standards but taking decisive steps towards their practical implementation. Technology, particularly that offered by SmartBarrel, emerges as a critical ally in this endeavor, providing the tools necessary for fostering a safe, compliant, and productive work environment.

Frequently Asked Questions

1. What are OSHA guidelines for electrical?

OSHA 1926 electrical standards are designed to ensure a safe working environment for handling electrical equipment and systems. They emphasize:

- Deenergizing equipment before any maintenance or repair to prevent accidental electrocution.

- Using lockout/tagout procedures ensures that deenergized equipment stays off and is not turned on accidentally until the work is completed safely.

- Employing insulating protective equipment to safeguard workers from potential electrical hazards. This could include gloves, mats, or shields designed specifically to insulate against electrical shock.

- Maintaining safe distances from energized parts, which involves keeping a safe distance or using insulating barriers to prevent contact with live electrical components.

These basic procedures are designed to minimize the risk of electrical accidents and injuries among workers handling or exposed to electrical systems and equipment. According to the Bureau of Labor Statistics, adherence to OSHA 1926 electrical standards significantly reduces the risk of electrical accidents on construction sites.

2. What does OSHA 1926 apply to?

The scope of OSHA 1926 standards is broad, applying to several key areas in the construction industry:

- Construction work, which includes tasks involved in constructing, altering, or repairing buildings and structures. This encompasses a wide range of activities from foundational work to finishing touches like painting and decorating.

- Projects covered under the Davis-Bacon Act, which pertains to federally-funded or assisted contracts for the construction, alteration, or repair (including painting and decorating) of public buildings or public works.

Understanding the scope of OSHA 1926 standards is crucial for ensuring compliance with safety and health provisions, safeguarding workers’ well-being throughout the construction project lifecycle. SmartBarrel’s suite of construction management solutions, including biometric time tracking and safety management, can play a pivotal role in ensuring compliance with OSHA 1926 standards and enhancing jobsite safety.

3. What is the most common OSHA electrical violation?

Common OSHA electrical violations tend to revolve around the following issues:

- Failure to prevent energy release during maintenance. This typically involves inadequate lockout/tagout procedures, allowing machinery to be unintentionally energized, posing serious risks to workers.

- Inadequate provision of personal protective equipment (PPE) and insufficient adherence to training requirements for safely handling electrical hazards can lead to accidents.

- Lack of audits. Skipping regular safety audits results in non-compliance issues going unnoticed until too late, increasing the likelihood of accidents and penalties.

Addressing these common pitfalls by implementing thorough safety protocols and regular audits can significantly reduce the occurrences of such violations.

4. What is the OSHA rule on electrical cords?

OSHA’s regulations concerning electrical cords are geared toward preventing accidents stemming from misuse or malfunctions. Key rules include:

- Portable cord- and plug-connected equipment must undergo inspections before usage. This examination should aim at identifying any external defects (like frayed cords or loose parts) and possible internal damage that might not be visible but could affect the equipment’s safe operation.

Adhering to this rule plays a vital role in minimizing electrical hazards, ensuring that all cord- and plug-connected equipment on a construction site operates safely and effectively.