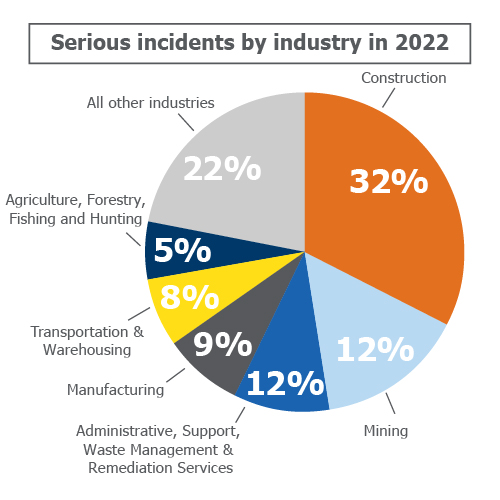

The construction industry continues to be one of the most hazardous sectors, with a high rate of fatal and non-fatal injuries compared to other industries. This underscores the ongoing need for stringent safety measures and compliance with established safety rules.

Safety is not just a regulation; it’s a necessity to ensure the well-being of everyone on a construction site.

According to HSE statistics, slips and trips, often resulting from poor site tidiness, accounted for 31% of specified major injuries in recent years. This piece of data is not just a statistic; it serves as a compelling argument for why maintaining cleanliness and order on-site is crucial.

Innovation in safety practices, including the adoption of wearable tech for monitoring worker health, is transforming construction site safety.

For instance, Related Urban Construction’s Compliance Management demonstrates how technology like SmartBarrel can significantly improve compliance management, reducing compliance reporting time by eight times and enhancing accuracy. This checklist embodies that future, providing an extensive guide designed for implementing vital safety measures effectively.

For more insights on maintaining site tidiness and reporting unsafe conditions, visit How to Prevent Construction Hazards on Your Job Site.

Key Takeaways for Enhancing Site Safety

A safety-first culture within the construction industry isn’t an option—it’s imperative. Recognizing this, our checklist aims at:

- Cementing the importance of legal compliance and protecting workers at all costs.

- Introducing actionable guidelines that cover a wide range of safety measures, from personal protective equipment (PPE) use to the proper handling and reporting of equipment malfunctions.

With these takeaways, specialty electrical subcontractors working on large commercial and residential projects can expect to not only meet but exceed construction site safety rules. Let this checklist, which serves as a construction site rules example, guide you through implementing safety guidelines effectively, ensuring a safe working environment for all involved.

Understanding Construction Site Safety

Construction site safety, defined as a comprehensive set of guidelines and procedures, forms the bedrock of preventing workplace accidents. These rules are designed to safeguard the health and well-being of workers by minimizing risks, preventing accidents and injuries, and ensuring compliance with legal and regulatory requirements.

The essence of construction site safety rules lies in their dual focus: protection of personnel and adherence to legal requirements.

The Lifesaving Impact of Safety Measures

Example of a Tidy Site for Preventing Accidents

This practice not only enhances safety but also fosters a more productive working environment.

Maintaining cleanliness isn’t just about aesthetics. It’s a critical safety strategy.

Slips, trips, and falls represent a significant portion of major injuries on construction sites, as reported by HSE statistics. A tidy site, therefore, is not a luxury—it’s a necessity.

Legal Requirements Shaping Safety Protocols

The legal requirement for induction training and the use of Personal Protective Equipment (PPE) underscores the importance of compliance. These regulations are not arbitrary; they are developed through extensive research and understanding of construction site hazards.

Ignoring these legal requirements doesn’t just jeopardize worker safety; it exposes companies to legal liabilities and potential fines.

Legal mandates serve a critical function—they provide a structured approach to ensuring worker safety. Compliance is paramount, not only as a measure of best practices but as an indispensable part of operating within the industry’s legal framework.

This relationship between construction site safety rules and legal requirements illustrates the comprehensive nature of safety protocols, emphasizing their role in fostering safer work environments.

In conclusion, understanding construction site safety is paramount for any construction operation. For instance, Prism Electric’s implementation of SmartBarrel’s time tracking solutions showcases the critical role of accurate time tracking in safety management, emphasizing the necessity of such technologies in ensuring construction site safety.

Transitioning from the foundational concepts of construction site safety, let’s explore specific rules and guidelines that are instrumental in achieving these safety objectives.

Prerequisites for Implementing Safety Measures

Assessing Site-Specific Hazards

Before the first tool is picked up, a thorough assessment of potential hazards is essential. This step lays the groundwork for a safe construction environment. Here’s why hazard assessment is crucial:

- Conducting a risk analysis involves evaluating all aspects of the construction site. This means looking at the type of work to be done, the tools and materials to be used, and the environment in which the work will take place.

- Identifying potential safety threats is not just about seeing the obvious dangers. It’s about understanding how different elements of a project can interact in ways that might create new risks.

This process of identifying hazards before work begins is outlined in “Risk Assessment and Safety Procedures.” These procedures emphasize the value of spotting potential issues early on. Doing so allows for the development of strategies to minimize or eliminate risks altogether.

Establishing a Safety Culture

Creating a culture that prioritizes safety, starting with a comprehensive safety induction process, is non-negotiable. SmartBarrel’s solutions support this by enhancing safety management on construction sites. Here’s how to foster this environment:

- Training and continuous education are the cornerstones of a safety-first mindset. Every worker, from day one, needs to understand the specific hazards of their workplace and how to protect themselves and their colleagues.

- Encouraging open communication about safety concerns plays a significant role in maintaining a safe environment. Workers should feel empowered to report potential hazards without fear of retribution.

The importance of a thorough safety induction for new workers cannot be overstated. It serves as an introduction for new workers to the site-specific hazards, safety procedures, and working conditions of a construction site. This concept of familiarizing staff with their surroundings before they start work is fundamental.

Assessing site-specific hazards and establishing a safety culture are critical. These steps lay the foundation for effective safety measures on construction sites.

Identifying potential threats and fostering a safe environment minimizes accidents and injuries.

Having established the need for thorough hazard assessments and the cultivation of a safety-first mindset, let’s explore practical safety guidelines and Personal Protective Equipment (PPE).

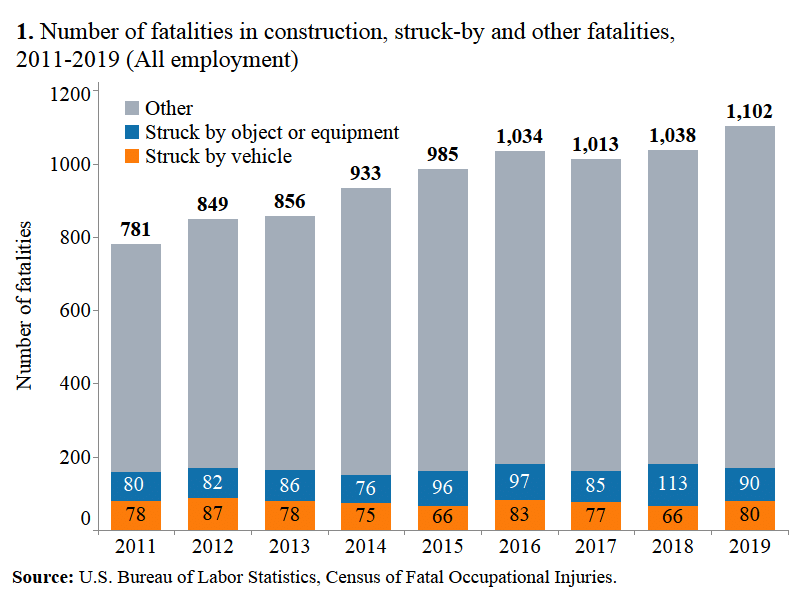

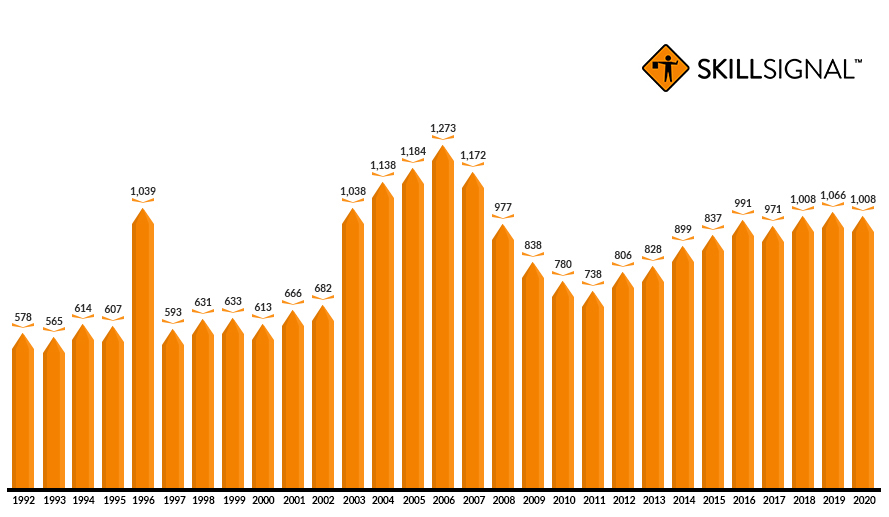

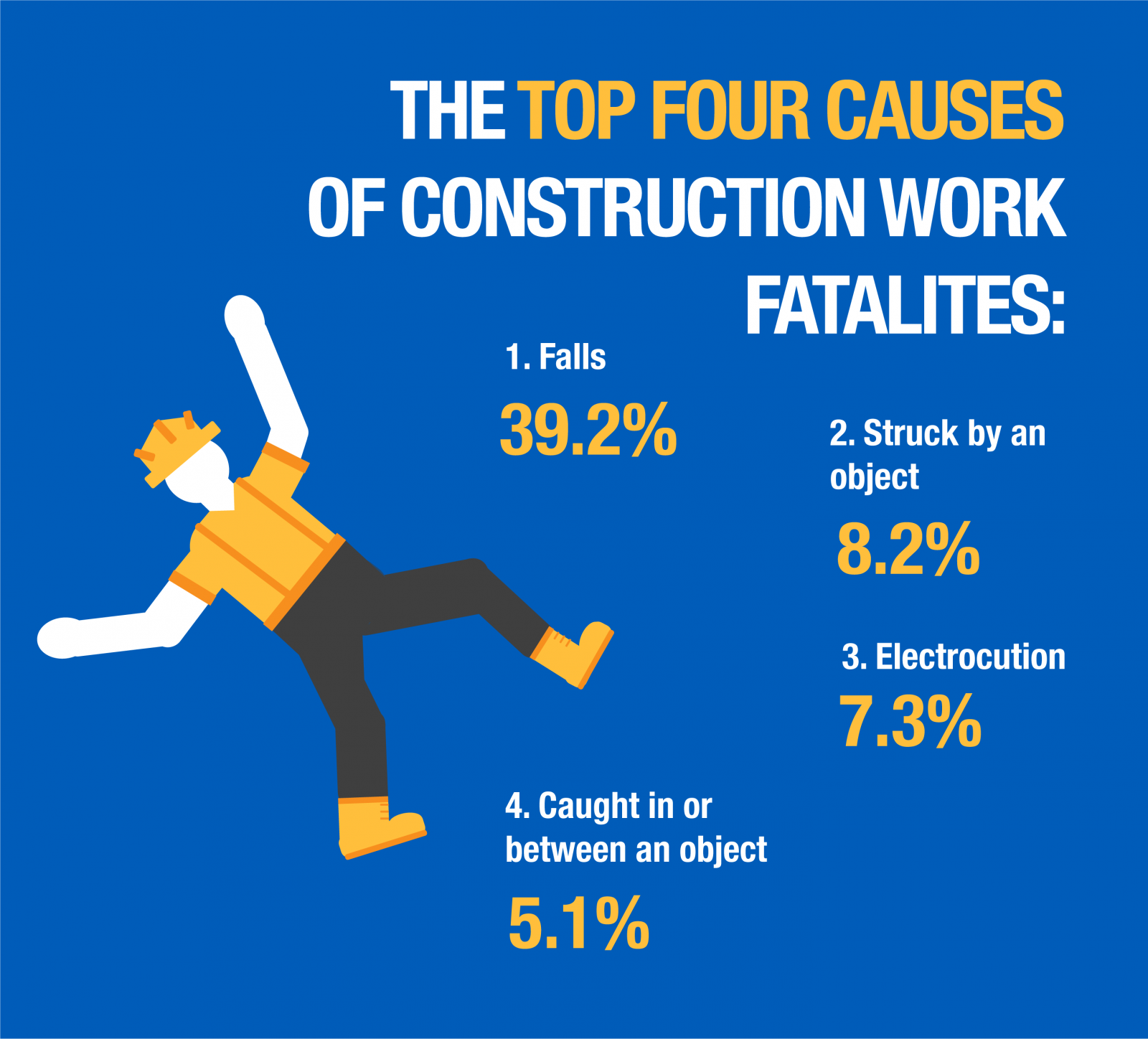

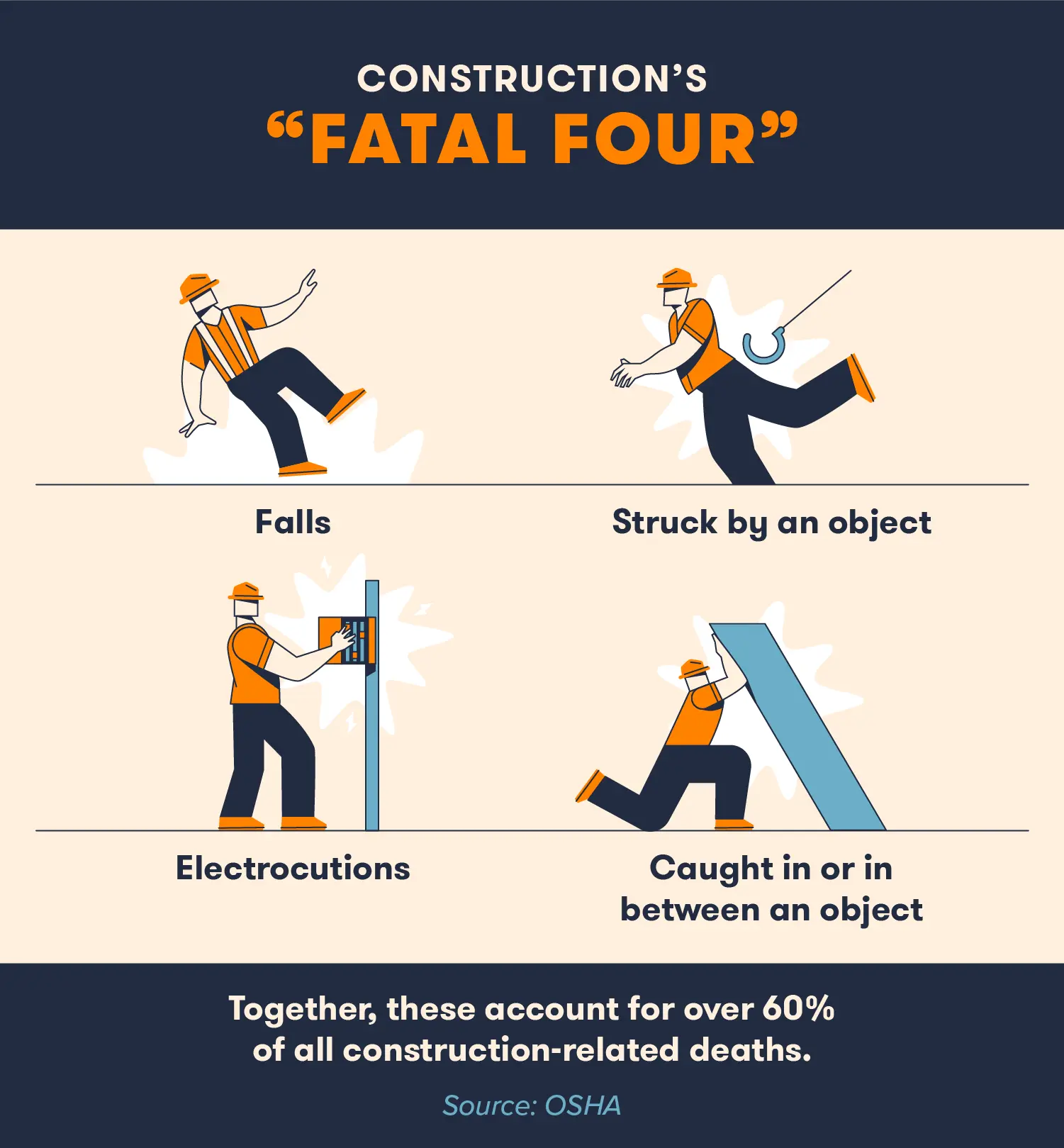

The chart ‘Construction’s Safety Statistics – SkillSignal’ highlights the importance of fall prevention and proper equipment handling.

Similarly, the ‘Fatal Four’ chart emphasizes the need to focus on preventing major accidents. Juneau Construction’s operational upgrade, detailed here, showcases how safety improvements and accurate time tracking via SmartBarrel contribute to a safer site. These tools transform safety from theory to practice, protecting lives.

Checklist for Construction Site Safety

Safety at a construction site is paramount, and adhering to a well-structured checklist, such as a construction site rules example, can significantly enhance safety measures. Let’s examine key aspects of construction site safety that are indispensable for protecting workers.

1. Conduct Regular Safety Inductions

Safety inductions are vital for every new worker on a construction site. These sessions serve multiple purposes:

- They inform workers about the specific hazards associated with the site.

- They cover critical safety procedures and emergency protocols.

- Inductions are legally required and must be site-specific, as per the Health and Safety at Work etc. Act 1974 and the Construction (Design and Management) Regulations 2015, highlighting legal obligations.

Customization of these inductions is crucial, ensuring they’re relevant to the unique features and risks of each site. Through regular safety induction sessions, workers become more aware of potential dangers, reducing the likelihood of accidents. According to HASpod, the principal contractor is responsible for ensuring all workers, including those from subcontractors, receive proper induction.

2. Enforce Personal Protective Equipment (PPE) Usage

The role of PPE in minimizing exposure to workplace hazards cannot be overstated. Various types of PPE are crucial for worker safety, including:

- Helmets, which provide essential head protection.

- Goggles, safeguarding eyes from potential hazards.

- Gloves, designed to shield hands from sharp objects and harmful chemicals.

- Safety harnesses, critical for fall protection in elevated work areas.

Employers play a critical role in providing and maintaining PPE. Innovative technologies, such as smart sensors and IoT integrated into PPE, have revolutionized its functionality. For instance, HSE Network highlights how advancements like AR in smart glasses can improve safety by providing real-time hazard alerts.

3. Maintain Site Tidiness to Prevent Accidents

A well-organized construction site is key to preventing many common accidents. Strategies for maintaining tidiness include:

- Scheduled clean-up operations

- Designated storage areas for tools and materials

- Clear labeling of hazardous zones

Connection between site tidiness and reduced accident rates is well-documented. By eliminating potential hazards like loose cables or construction debris, the risk of slips, trips, and falls significantly decreases.

4. Adhere to Safety Guidelines and Procedures

Following established safety guidelines and procedures is non-negotiable for ensuring worker safety. Key examples include:

- The use of guardrails to prevent falls

- Safe operating practices for heavy machinery

- Regular risk assessments to identify new hazards

These guidelines are developed based on a thorough understanding of construction site risks and are essential for maintaining a safe working environment.

5. Ensure Proper Use and Maintenance of Tools

The significance of using the right tools and keeping them in good condition cannot be understated. Regular equipment maintenance checks prevent malfunctions that could lead to accidents. Workers should be trained on:

- Choosing the correct tool for the task at hand

- Performing pre-use inspections

- Reporting any defects immediately

6. Implement Reporting Protocols for Incidents

A robust system for reporting accidents, near misses, and defects plays a critical role in improving site safety. Such protocols ensure:

- Timely response to incidents

- Documentation for legal compliance

- Lessons learned are applied to prevent future accidents

The reported figures by HSE emphasize the importance of diligent reporting and documentation. Additionally, the integration of smart sensors and IoT technology in PPE, as discussed by HSE Network, showcases the evolving landscape of worker safety through technology.

7. Operate Heavy Machinery Safely

Safe operation of heavy machinery, a core aspect of heavy machinery safety, is essential to avoid serious accidents. Operators should be fully qualified and aware of the risks, including:

- Ensuring machinery is in good working order before use

- Knowing the machine’s operating capacity

Misuse of heavy machinery is a leading cause of fatal accidents in construction.

8. Promote Effective Communication and Safety Meetings

Regular safety meetings and clear communication channels are vital for reinforcing safety measures. Tips for effective communication include:

- Frequent updates on safety protocols

- Open forums for workers to discuss concerns

- Sharing lessons learned from past incidents

9. Consider Environmental Factors and Emergency Preparedness

Taking into account environmental factors and having a solid emergency preparedness plan can greatly reduce the impact of unexpected events. Elements of an effective emergency preparedness plan include:

- Clear evacuation routes to ensure safe exits.

- Designated EAP Managers, responsible for overseeing emergency responses.

- Comprehensive training on emergency response procedures for all personnel.

Emergency plans must address a wide range of potential scenarios, ensuring readiness for any situation.

The following chart illustrates the key components of an effective emergency action plan.

10. Leverage Technology for Safety Management

Innovations in safety technology offer promising solutions for enhancing construction site safety. For instance, Kiewit improved their safety management and compliance by deploying SmartBarrel devices for real-time, accurate attendance tracking, as detailed in our case study. By incorporating technology into safety management, construction sites can achieve higher levels of safety and compliance. Learn more about how SmartBarrel’s solutions can help with this through our Construction Site Safety Management page.

As we consider these critical elements of construction site safety, it becomes evident how comprehensive approaches can significantly reduce risks. Implementing these measures requires diligence but pays dividends in creating safer working environments. Having explored these essential safety rules, it is now time to look beyond mere compliance towards fostering a culture of safety that permeates every aspect of construction work.

Conclusion: Commitment to Safety is Key

The checklist above is more than a set of instructions; it’s a blueprint for creating a safer construction environment. By embedding these practices into daily operations, we underscore our commitment to safeguarding lives and maintaining a productivity-focused workplace.

Here’s a summary of the path forward:

- Embrace a safety-first culture that prioritizes worker well-being above all.

- Ensure strict compliance with legal requirements to protect your team and organization.

- Adopt technology solutions like SmartBarrel to streamline safety management.

The construction industry continues to be one of the most hazardous sectors, with a high rate of fatal and non-fatal injuries compared to other industries. However, through diligent application of these safety measures, we can mitigate risks.

The construction site rules example, construction site safety rules, and safety guidelines articulated here form the cornerstone of a robust safety program. They represent not just best practices but essential steps towards achieving a zero-incident workplace.

The ongoing development of new safety technologies and practices, such as wearable tech for monitoring worker health and safety, suggests a future where construction site safety is enhanced through innovation.

In light of the compelling data presented in the Adoption of Technology on the Jobsite chart, it’s clear that integrating technology into safety protocols isn’t just advantageous—it’s becoming the industry standard.

For those ready to take the next step in safety management, exploring SmartBarrel’s suite of construction management solutions offers a promising avenue. A case in point is the NV2A Group, which needed to track workers and performance more efficiently. By enforcing the use of SmartBarrel for on-site time tracking, they improved efficiency and provided a reliable record for safety. Learn more about this success story at NV2A Group’s Attendance Management.

In conclusion, let’s remember: safety is not a one-time effort but a continuous journey. By adopting these comprehensive safety measures and leveraging innovative technologies, we pave the way for a safer, more efficient construction industry. Let’s work together to build an environment where every worker returns home safely at the end of the day.

Frequently Asked Questions About Construction Site Safety

Ensuring the safety of construction workers is paramount. Adhering to the following on-site rules is not just a matter of compliance but a commitment to the well-being of every individual on the site:

1. What are some on-site rules?

On-site rules essential for maintaining safety not only include practical measures but also adhere to specific legal requirements. For instance, safety inductions for new workers are mandated by law to ensure they are familiar with the site’s safety protocols and emergency procedures.

These rules form the basis of a comprehensive safety program tailored to the unique challenges of construction sites, incorporating both traditional practices and legal obligations to foster a secure working environment.

- Personal Protective Equipment (PPE) usage is crucial to shield workers from potential harm. Innovations in PPE, such as smart helmets with built-in communication systems, provide enhanced safety beyond traditional gear like goggles and safety harnesses.

- Site tidiness is critical in preventing accidents such as slips, trips, and falls by keeping the construction area organized and free of unnecessary debris.

- Reporting procedures for incidents, near misses, and equipment defects ensure that issues are documented and addressed promptly to avoid future accidents.

2. What are the 10 safety rules?

A comprehensive safety plan encompasses a wide range of protocols, including:

- Conducting regular safety inductions for new workers

- Enforcing the use of Personal Protective Equipment (PPE)

- Maintaining site tidiness to prevent accidents

- Adhering to established safety guidelines and procedures

- Ensuring proper use and maintenance of tools and equipment

- Implementing detailed reporting protocols for incidents

- Operating heavy machinery with utmost caution and proper qualifications

- Promoting effective communication and regular safety meetings

- Considering environmental factors is critical, and having an emergency preparedness plan that accounts for these variables ensures a swift response to incidents. For example, adapting evacuation procedures based on seasonal weather changes can significantly enhance site safety.

- Leveraging technology for efficient safety management

These ten rules form the cornerstone of effective safety management on construction sites, emphasizing the importance of a proactive approach to preventing accidents and ensuring a safe working environment.

3. What are the 10 general safety rules in a workshop?

In workshops, safety rules focus on preventing accidents through:

- Mandatory use of Personal Protective Equipment (PPE) according to the task at hand

- Regular maintenance checks on tools to ensure they’re in proper working condition

- Keeping the workshop tidy to avoid hazards associated with clutter and disorganization

- Proper storage of hazardous materials

- Use of guards on equipment to prevent contact with moving parts

- Effective ventilation systems to manage dust and fumes

- Adequate lighting to enhance visibility

- Emergency stop buttons on machines for quick shutdowns in case of danger

- Clear markings for emergency exits

- Training and drills for emergency response

These rules emphasize the importance of a safe working environment in workshops, mirroring many principles applicable to larger construction sites.

4. What are three rules that construction workers need to follow?

Three pivotal rules include:

- Personal Protective Equipment (PPE) usage: Workers must wear appropriate PPE at all times to protect against specific hazards present on the construction site.

- Proper use of tools and equipment: Selecting the right tool for the job and ensuring it is in good condition before use helps prevent accidents.

- Incident reporting: Any accidents, near misses, or unsafe conditions must be reported immediately to prevent recurrence.

Following these guidelines helps maintain a baseline of safety, fostering an environment where everyone is protected.

Case studies like AG Structures’ Time Tracking Transformation and NV2A’s Workforce Management on a Private Island highlight the importance of technology in enforcing safety measures and managing workforce efficiently. AG Structures required a reliable time tracking solution for complex projects, which was fulfilled by implementing SmartBarrel’s device and software, streamlining payroll processes and ensuring accurate attendance records. Similarly, NV2A managed over 40 workers on a remote island, leveraging SmartBarrel for easy reporting and time tracking, which reduced payroll calculation time and provided flexible time-rounding rules.